powder dip coating line

Precision Engineered for Peak Performance

Ideal for high-efficiency production and complex geometries, our powder dip coating line ensures uniform, durable finishes through an eco-friendly process with zero VOC emissions. Engineered for metals, alloys, and heat-resistant components, it delivers exceptional corrosion resistance and vibrant aesthetics. Customizable immersion parameters and rapid-curing technology optimize throughput, while powder reclamation reduces waste.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

what is powder dip coating line

A powder dip coating line is a system that applies a protective powder coating to a material, typically metal, through a dipping process. It involves immersing the part into a tank containing a powder coating material, where electrostatic attraction and heat curing create a durable, uniform finish.

Advantages of powder dip coating line

- Durable and Uniform Finish: Powder coating provides a hard, chip-resistant finish, better than conventional liquid paints.

- Corrosion Resistance: Powder coating offers excellent protection against corrosion and rust.

- Versatile Application: It can be applied to various metal products, including furniture, appliances, automotive components, and more.

- Environmentally Friendly: Powder coating is a solvent-free process, reducing waste and pollution.

- Efficiency: The dipping process can be highly efficient, especially for parts with complex shapes or hard-to-reach areas.

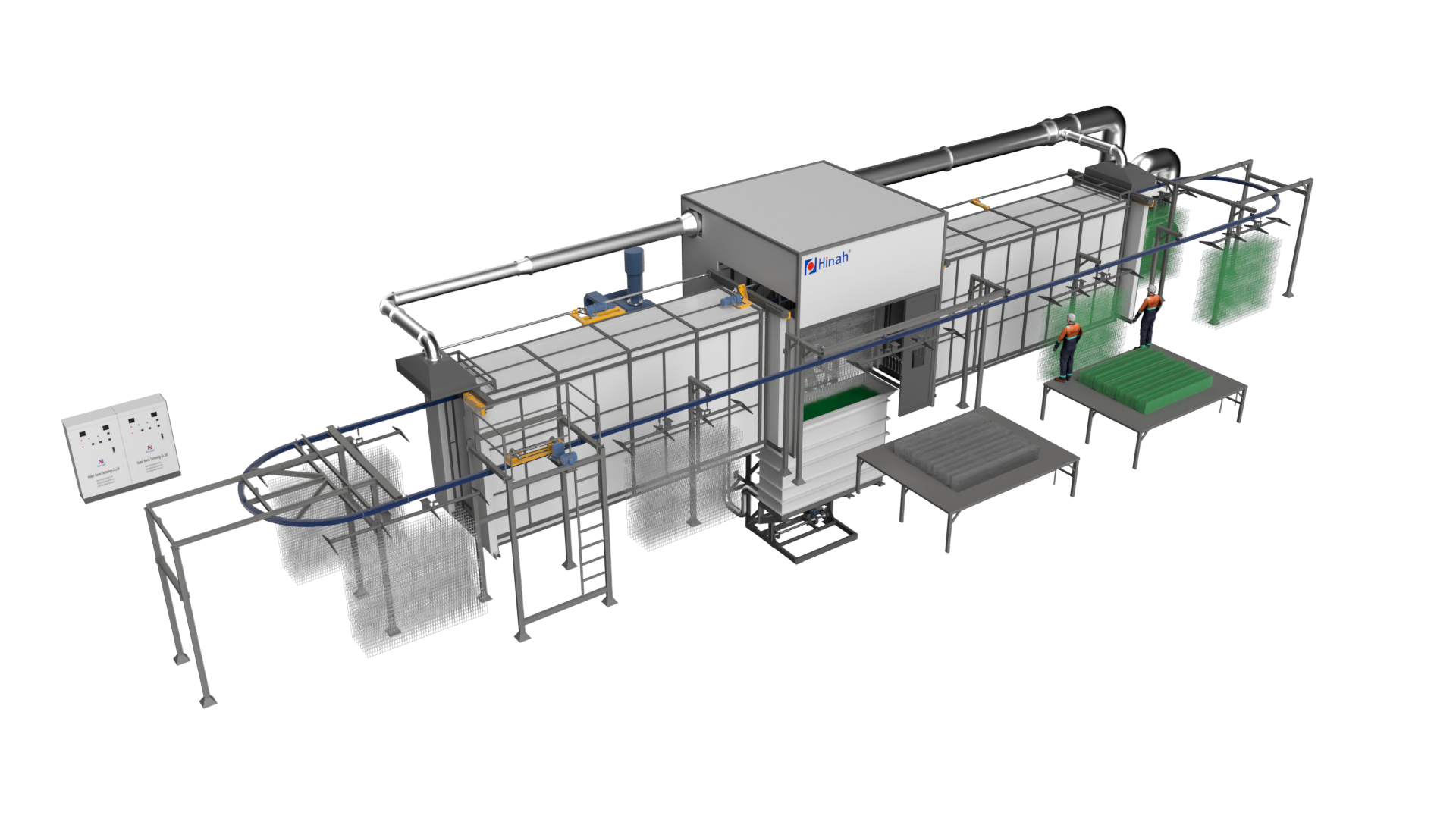

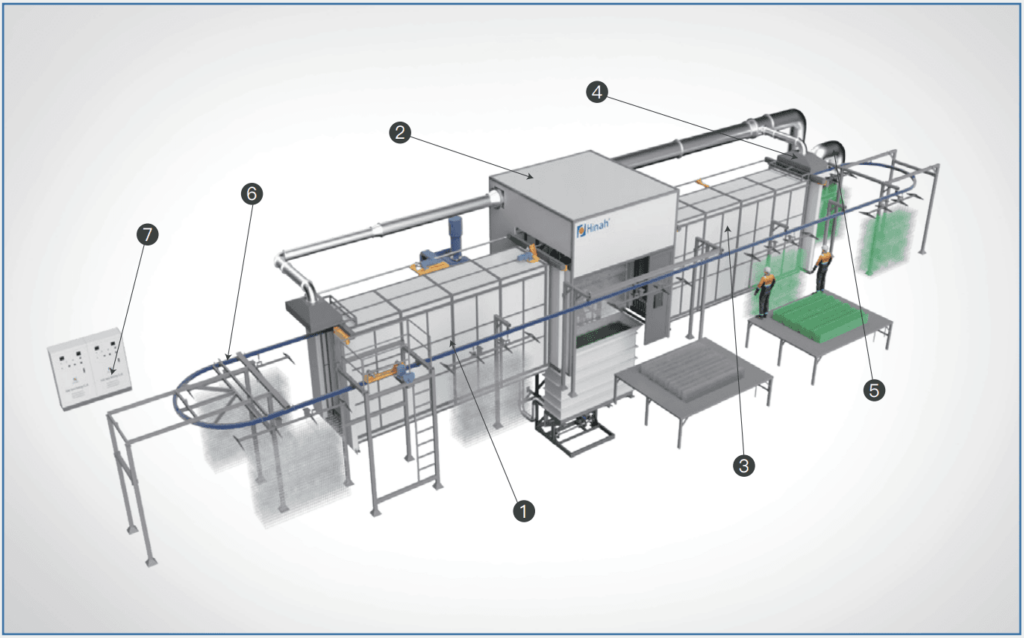

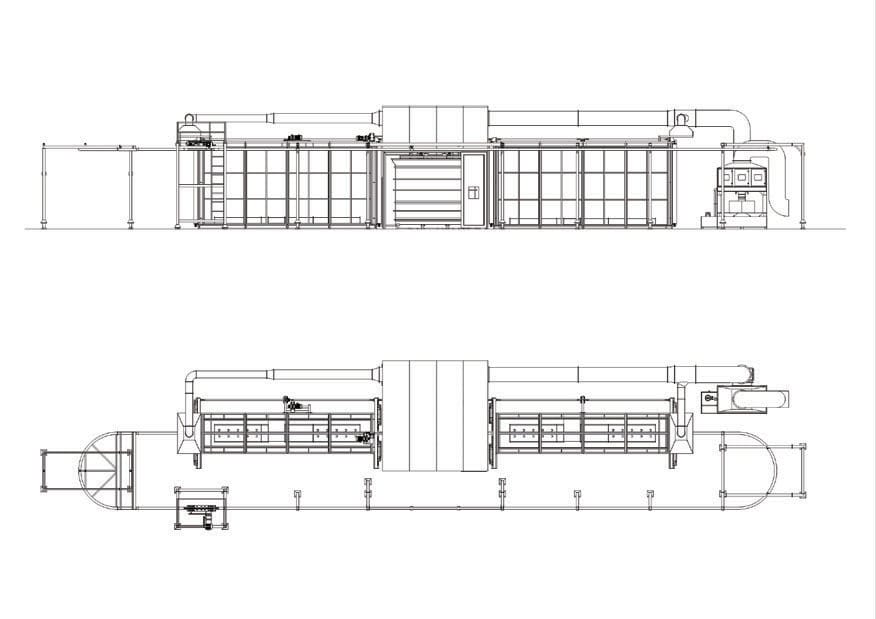

Components of powder dip coating line

1. Preheating Furnace System: Heats parts to a specific temperature before coating to ensure optimal adhesion and surface preparation.

2. Automatic Plastic Dipping System: Automatically immerses preheated parts into a fluidized powder bed for uniform coating application.

3. Curing Furnace System: Bakes coated parts at controlled temperatures to melt and solidify the powder into a durable finish.

4. Exhaust Air Collector: Captures fumes and airborne particles generated during dipping and curing processes.

5. Exhaust Air and Dust Purification Device: Filters and treats collected emissions to meet environmental standards before release.

6. Conveyor Chain: Transports parts seamlessly between stations, ensuring synchronized movement through the production line.

7. Electric Control Cabinet: Centralized control unit managing automation, temperature, timing, and safety parameters for the entire system.

Case Show

powder dip coating line for fence mesh

Our advanced liquid coating system revolutionizes surface treatment for diamond saw blade manufacturing. This automated line features precision-controlled spray nozzles and optimized viscosity management, ensuring uniform coating application across irregular blade surfaces. The integrated IR-curing tunnel achieves rapid polymerization while maintaining coating integrity at high temperatures. With 23% increased production efficiency and 15% material savings compared to traditional methods, this solution helps manufacturers enhance product durability and corrosion resistance – critical for extending cutting tool lifespan in harsh working environments.

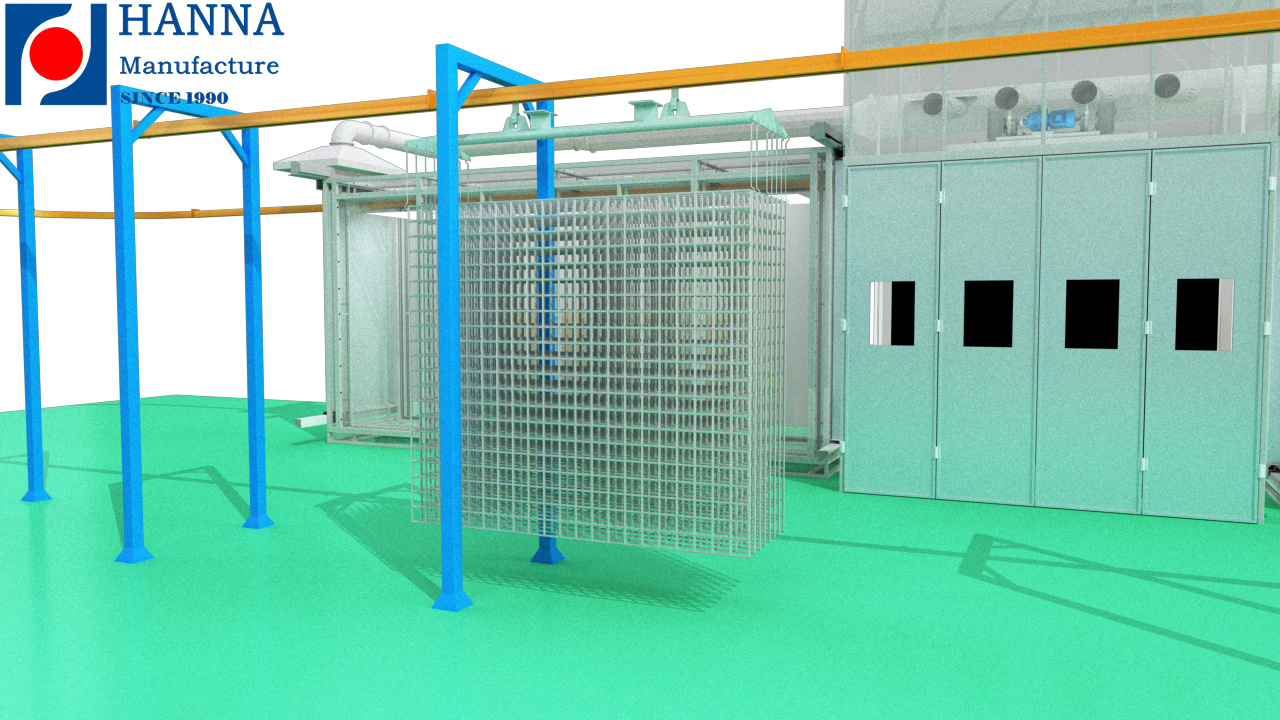

powder dip coating line for metal fences

This powder dip coating line is tailored for metal fence manufacturing, utilizing a fully immersive dip-coating process to achieve seamless, high-performance finishes. Components such as steel, aluminum, or wrought iron fences are submerged in a fluidized powder bed, ensuring complete coverage—even on intricate geometries, tight corners, and textured surfaces. The system begins with a multi-stage pre-treatment (cleaning, phosphating) to maximize adhesion, followed by controlled immersion and a high-temperature curing cycle that bonds the coating into a durable, weatherproof layer resistant to rust, scratches, and UV degradation.

Competitive Advantages

- High Transfer Efficiency & Material Utilization: Powder dip coating lines minimize waste compared to spray coating methods. Excess powder simply drips back into the dip tank for reuse, leading to a high transfer efficiency and reduced material costs.

- Uniformity & Coating Quality: Dip coating allows for the application of a uniform and consistent coating thickness across the entire surface of the part.

- Coating Complexity & Accessibility: The dip coating process can coat intricate shapes and areas that are difficult to reach with spraying methods.

- Automation & Efficiency: Dip coating processes are well-suited for automation, leading to increased production speed, reduced labor costs, and consistent quality.

Product images

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.