powder coating equipment

Precision Engineered for Peak Performance

Our advanced powder coating equipment provides efficient, eco-friendly solutions for industrial finishing. Designed for metals, alloys, and heat-resistant components, these equipments ensure uniform, durable finishes with zero VOC emissions and minimal waste through smart powder reclamation. Customizable parameters and automation adapt to complex geometries, delivering corrosion resistance and vibrant aesthetics.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

Powder Coating Robot

Powder Coating Booth

Powder Curing Oven

Pretreatment System

Conveyor System

Electric Control System

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

Main Equipments

powder coating(painting) robot

HANNA powder coating robots are mainly divided into two types: drag teaching programming and visual automatic programming, which are currently the two favorites of customers. Our powder coating(painting) robot has passed the quality management system, safety certification and explosion proof certificate. To ensure that you get what you really need, our factory authorized technical team will help you deal with all the details and directly achieve your goals. From the initial design to delivery, HANNA will take care of everything. In addition, we will provide assistance in installation, fine-tuning and training until your system is ready.

powder coating booth

Our powder coating booth solutions offer two specialized configurations: The Fast Color Change Booth enables rapid color transitions (<15 minutes) with anti-contamination airflow technology, perfect for multi-color production lines. Meanwhile, the Filter Recovery Booth prioritizes maximum powder reclamation (99.5% efficiency) through cyclonic filtration, ideal for high-volume single-color operations. Whether handling frequent color switches or continuous production, our booths deliver precision finishing with minimal downtime.

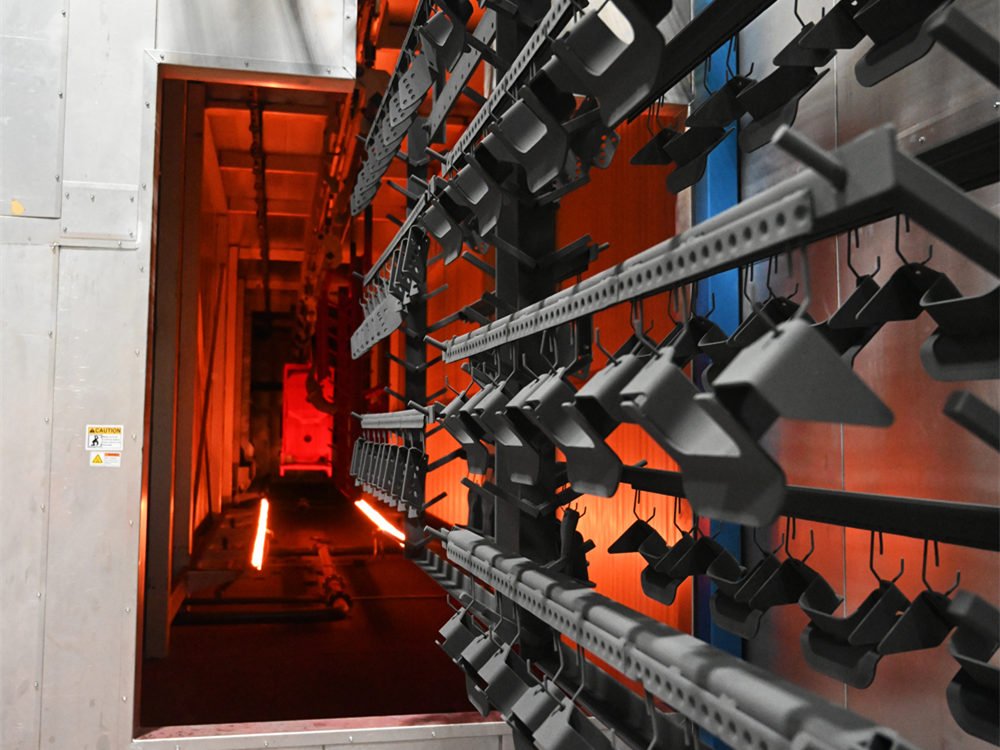

powder coating curing oven

Powder coating curing ovens are essential for creating durable, high-quality finishes by evenly heating coated surfaces to bond and cure the powder material. Our solutions include three specialized types: the camel back curing oven, featuring an arched design for large or heavy components with vertical space optimization; the tunnel curing oven, designed for continuous high-volume production lines to ensure efficient throughput; and the batch curing oven, offering flexible processing of small batches or complex-shaped items. Each type delivers consistent heat distribution and energy-efficient performance to meet diverse industrial needs while maintaining workflow compatibility.

powder coating pretreatment system

Our powder coating pretreatment systems prepare surfaces for optimal coating adhesion through thorough cleaning and chemical treatment. We offer two effective methods: Spray Pretreatment efficiently processes components using high-pressure nozzles to apply cleaning agents and conversion coatings, ideal for medium-sized parts requiring fast cycle times and water conservation. Dip Tank Pretreatment immerses products in sequential chemical baths, ensuring complete coverage for complex geometries or heavy-duty substrates.

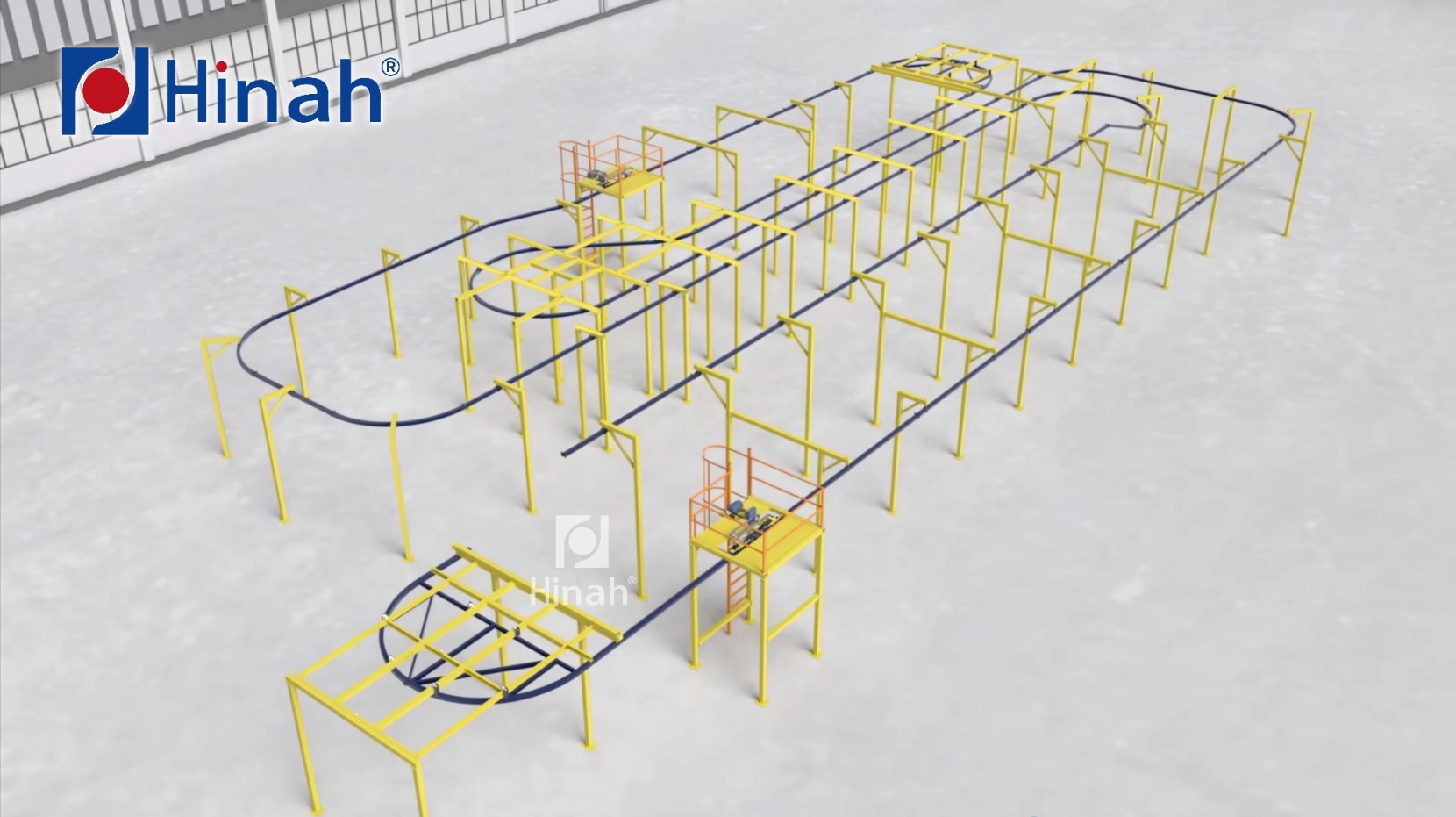

powder coating conveyor system

Our powder coating conveyor systems ensure precise material handling throughout the coating process, offering three optimized solutions: The Automatic Conveyor utilizes PLC-controlled tracks for high-speed, unmanned operation, perfect for mass production with repeatable positioning accuracy. The Power & Free Conveyor provides flexible buffering and variable speed control through independent trolleys, enabling simultaneous processing of mixed batches in complex layouts. For specialized applications, the Manual Conveyor offers cost-effective portability with adjustable rollers/rails, ideal for prototyping or oversized components.

Electric Control System

The Siemens color touch screen offers intuitive operation with a graphical interface, enabling operators to directly set critical spraying parameters (e.g., voltage, pressure, curing settings) on the screen. It features real-time system diagnostics for pre-operation checks and automatically stores alarm histories with error details, ensuring quick troubleshooting. The interface also supports program presets for efficient batch processing and consistent coating quality control.

Environmental Protection Equipment

Our powder coating line also integrates advanced environmental protection systems to ensure sustainable operations. The Wastewater Treatment Unit employs multi-stage filtration with pH neutralization and chemical precipitation processes, effectively removing heavy metals and suspended solids to meet ISO 14001 discharge standards. For emissions control, the Exhaust Gas Treatment System combines catalytic oxidation chambers with activated carbon adsorption towers, achieving >98% removal efficiency of VOCs (volatile organic compounds) and airborne particulates.

Case Show

Large cyclone recovery powder coating booth

A large cyclone recovery powder coating booth is a system designed to capture and recycle overspray powder during the powder coating process, reducing waste and improving efficiency. These booths utilize a cyclone system to separate powder from the airflow, followed by a cartridge filter unit to capture any remaining ultra-fine particles. This technology is crucial for high-volume powder coating jobs and helps create a dust-free workshop.

In essence, a large cyclone recovery powder coating booth is a critical component of any powder coating operation, providing a cost-effective and efficient solution for capturing and recycling overspray powder.

Automated conveyor system in powder coating line

Automated conveyor systems streamline powder coating lines by efficiently transporting parts through various stages, from pretreatment to curing. Automated conveyor systems ensure parts move through the process at a consistent pace, leading to uniform coating thickness and coverage, significantly reduce the need for manual handling, freeing up workers for other tasks.