Home » Products » Powder Coating Equipment » Powder Coating Pretreatment System

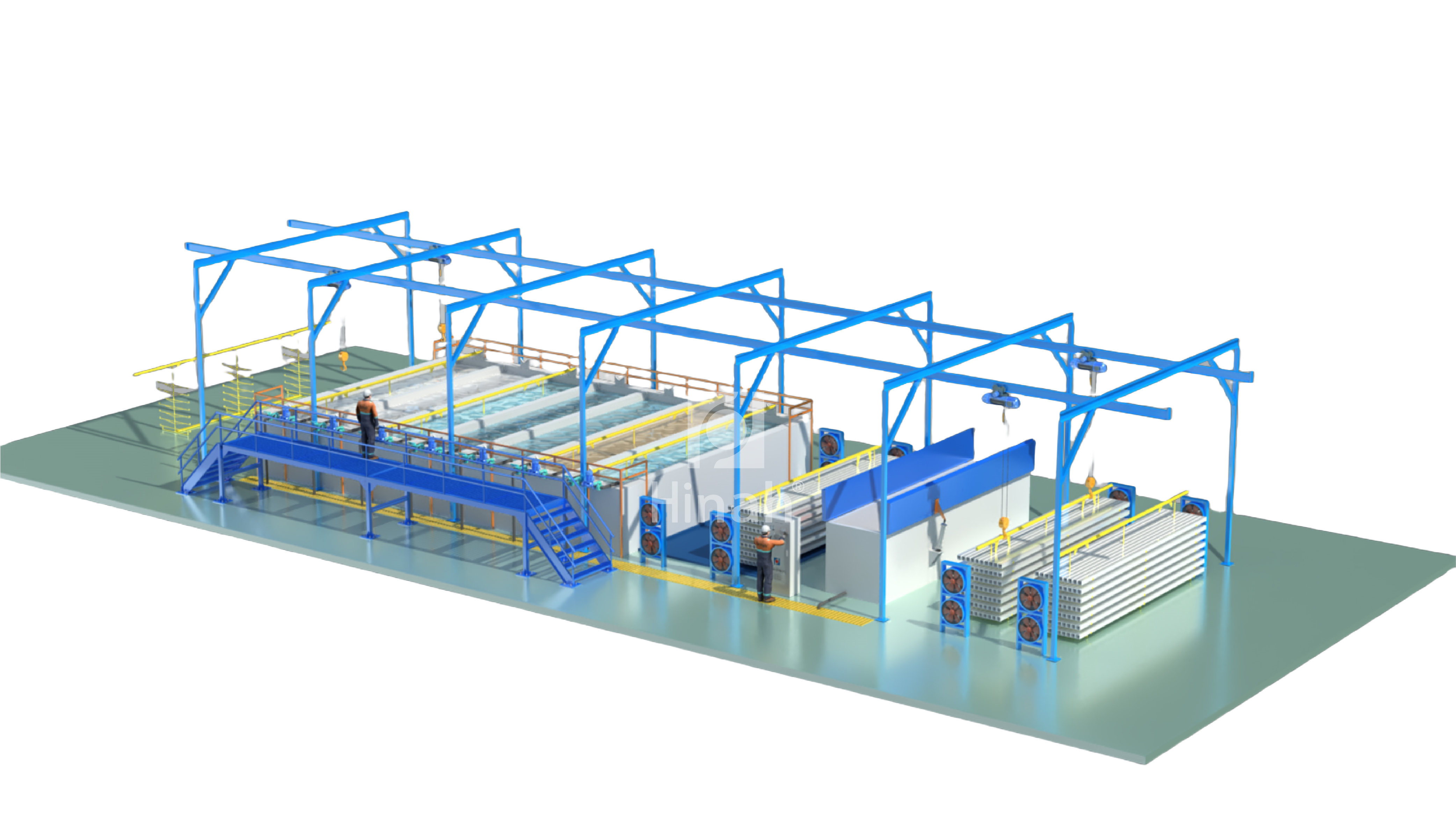

powder coating pretreatment system

Precision Engineered for Peak Performance

A powder coating pretreatment system prepares metal surfaces for powder coating by cleaning, etching, and conditioning them. This process ensures proper adhesion and a long-lasting finish. It typically involves multiple stages, including degreasing, rinsing, and potentially phosphating or chromating.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

product details

type 1: Spray Pretreatment

Powder coating pretreatment refers to the processes used to prepare a surface before applying powder coating, ensuring proper adhesion and a durable finish. Spray pretreatment involves cleaning and treating the surface by spraying cleaning agents and chemicals. This method is efficient and suitable for high-throughput production.

- Uniformity: Spray pre-treatment sprays the cleaning agent and treatment solution uniformly over the entire product surface, ensuring that every area is adequately cleaned and treated.

- Efficiency: spray pre-treatment enables the cleaning and treatment process to be completed in a short time, making it suitable for high throughput production environments and increasing production efficiency.

- Flexibility: Spray pre-treatment can be adapted to different product shapes and sizes for a wide range of product types and sizes.

- Resource-saving: Compared to immersion tank pre-treatment, spray pre-treatment typically requires less cleaning agent and treatment fluid, thus reducing resource consumption.

type 2: Dip Tank Pretreatment

Dip tank pretreatment is a process where metal parts are immersed in a chemical solution to prepare the surface for powder coating or other finishes. This method is particularly effective for cleaning, etching, and creating a conversion coating to enhance adhesion and corrosion resistance. It’s commonly used for complex geometries where spray systems might not reach all areas.

- Effective Cleaning:

The immersion process ensures thorough cleaning of the entire surface, even in hard-to-reach areas. - Enhanced Adhesion:

The conversion coating improves the bond between the metal and the final finish. - Improved Corrosion Resistance:

The conversion coating provides a layer of protection against corrosion. - Versatility:

Dip tank pretreatment can be used for various metal types and finishes, including powder coating, paint, and electroplating.

product Key Stages

- Cleaning: This step removes contaminants like oil, grease, dirt, dust, and rust. Alkaline washes are common for this purpose.

- Conditioning: This step prepares the surface for the subsequent conversion coating.

- Conversion Coating: This step (such as phosphating or chromating) creates a layer on the metal surface that improves adhesion and corrosion protection.

- Rinsing: Rinsing removes any residual chemicals from the surface.

- Drying: The final stage involves drying the pretreated metal parts.

product video

Competitive Advantages

- Compact and Space-Efficient Layout: Streamlined spraying mode shortens the system line length, optimizing floor space utilization and reducing facility footprint for cost-effective operations.

- Advanced Sealing and Ventilation Technology: Water-sealed design isolates steam at the shed body’s top, while integrated wind-through devices prevent acid gas and vapor accumulation, ensuring a safe and stable working environment.

- Durable Stainless Steel Construction: High-quality stainless steel materials for the shed body, cylinder block, and spray pipes, combined with precision welding techniques, guarantee corrosion resistance and a service life exceeding 15 years.

- Optimized Flow Control System: Contoured baffles and smooth transitions between sections create a controlled flow field for each process stage, effectively preventing cross-flow and ensuring uniform treatment quality.

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.