automatic powder coating line

Precision Engineered for Peak Performance

Elevate your production with fully customized automatic powder coating systems designed to meet your exact specifications. Our solutions combine cutting-edge technology, unmatched reliability, and seamless integration to boost efficiency, ensure flawless finishes, and minimize operational costs. Perfectly tailored for industries seeking scalable, intelligent automation.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

What is automatic powder coating line

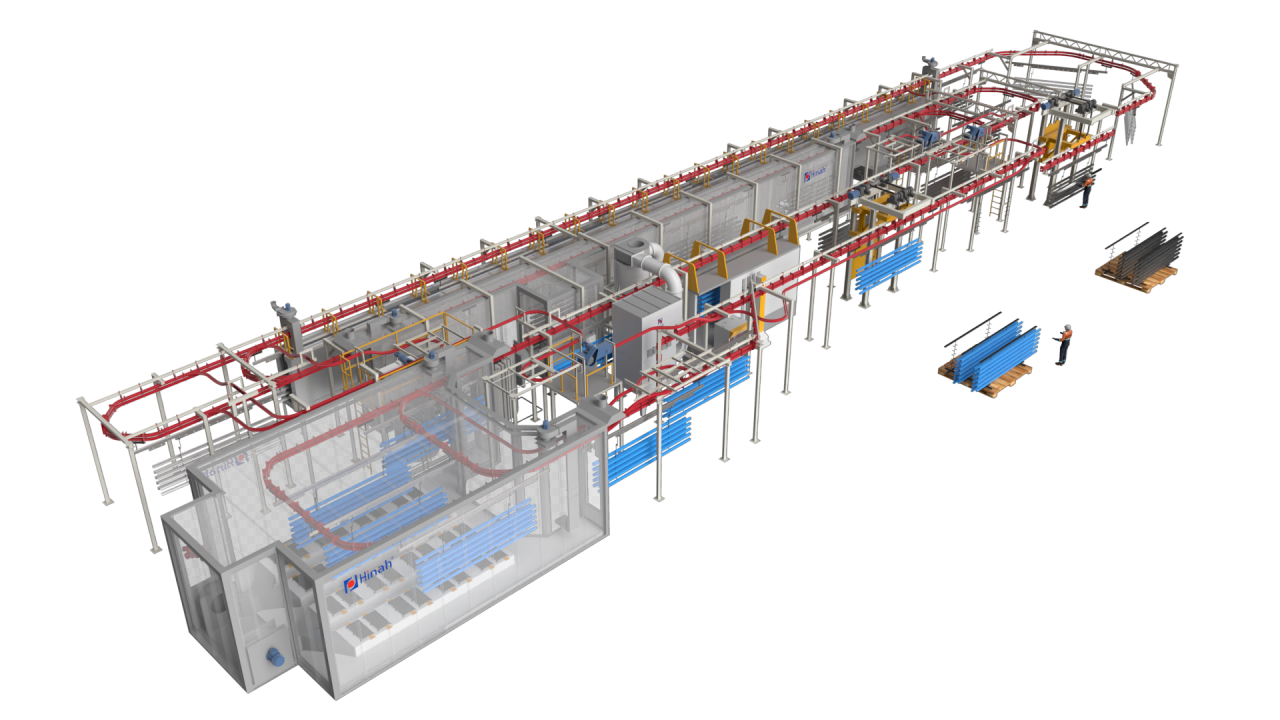

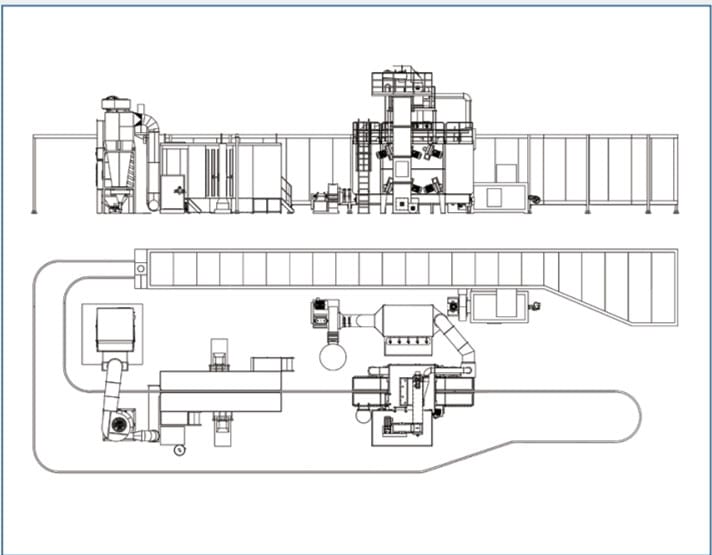

An automatic powder coating line is a system that automates the process of applying powder coatings to metal parts. It typically includes a conveyor, spray guns, an electrostatic spray system, a curing oven, and a control system. This system moves parts through a sequence of steps, including pretreatment, powder application, curing, and cooling, ensuring consistent and efficient coating.

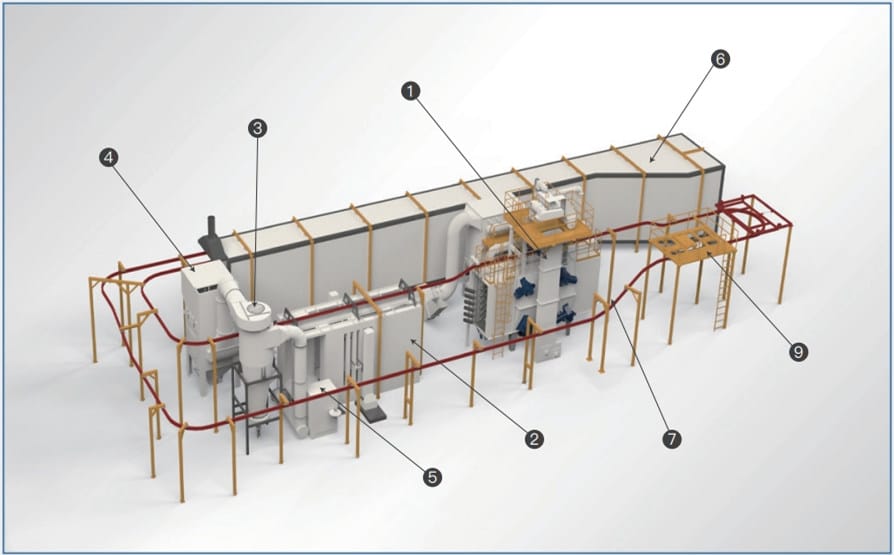

Components of automatic powder coating line

① Shot blasting pre-treatment: Ensures optimal surface adhesion by thoroughly cleaning and roughening substrates using high-speed abrasive materials.

② Powder coating booth room: Ensures optimal surface adhesion by thoroughly cleaning and roughening substrates using high-speed abrasive materials.

③ Large cyclone recovery device: Provides a controlled, dust-free environment for precise and uniform powder application.

④ Secondary filter element recovery device: Enhances powder recovery accuracy with advanced filtration, ensuring minimal waste and clean air emissions.

⑤ Powder supply center: Automatically feeds and mixes powder coatings for consistent color and quality throughout production.

⑥ Curing oven system: Delivers precise temperature control to solidify coatings into durable, smooth finishes.

⑦ Conveyor chain: Transports parts seamlessly through all stages of the coating process with adjustable speed settings.

⑧ Chain tensioner: Maintains optimal conveyor chain tension to prevent slippage and ensure uninterrupted operation.

⑨ Chain drive: Provides reliable power transmission to the conveyor system, engineered for heavy-duty performance.

Case Show

automatic powder coating line for aluminium profiles

Designed for high-volume aluminum profile manufacturers, this line delivers flawless finishes with uniform thickness, ideal for architectural and industrial applications. The system integrates advanced electrostatic spray technology and energy-efficient curing ovens to ensure corrosion resistance, UV durability, and smooth aesthetics. Customizable conveyor speeds and booth configurations accommodate profiles of any length or complexity.

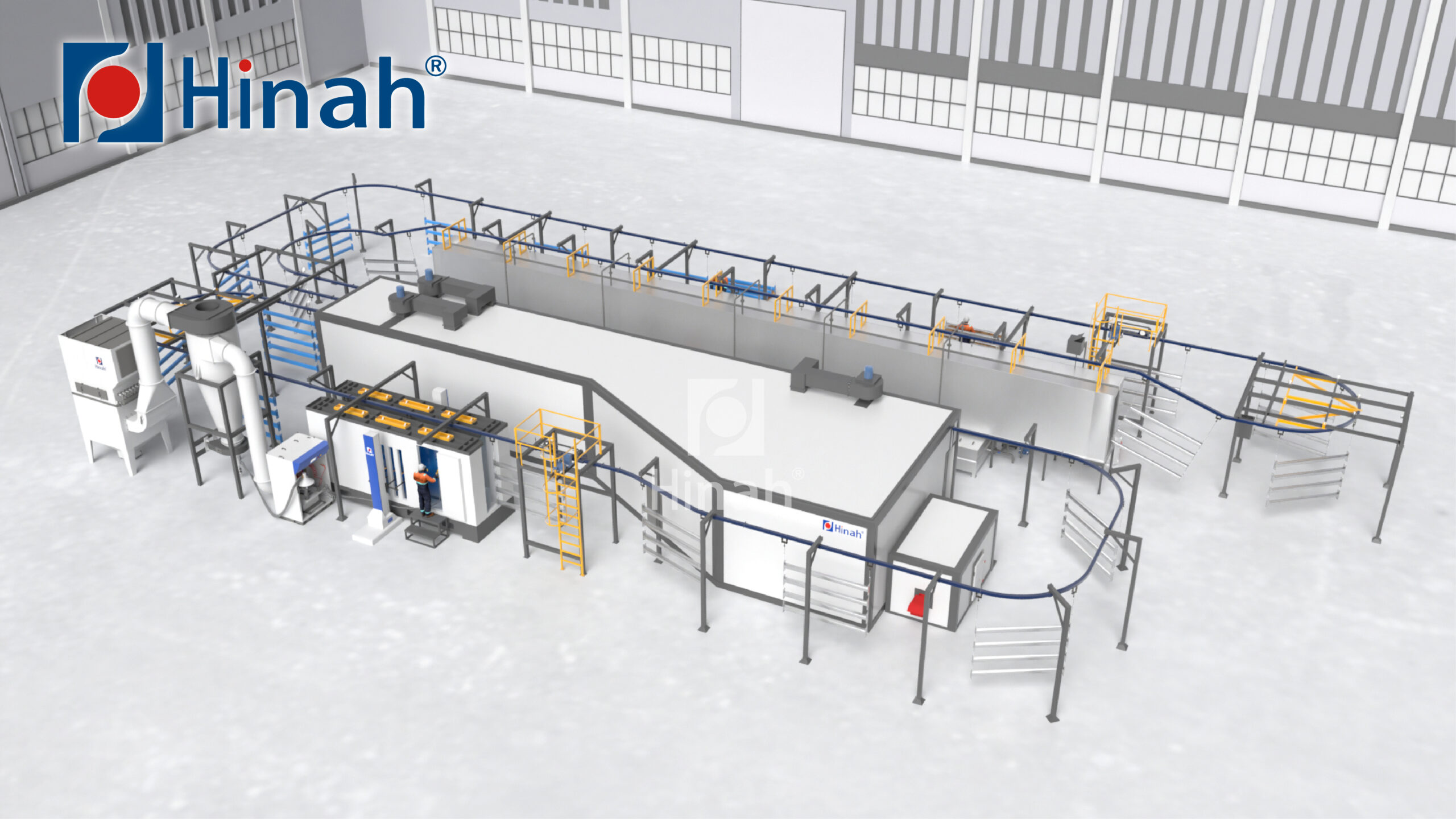

automatic powder coating line for iron sheets

Built to handle thick-gauge iron sheets, this line delivers ultra-durable, corrosion-resistant coatings perfect for construction, machinery, and agricultural equipment. The system features high-pressure shot blasting for flawless surface prep, precision electrostatic sprayers for uniform coverage, and rapid-cure ovens that reduce cycle times by 25%. Ideal for large-scale production of weatherproof, abrasion-resistant finishes.

Competitive Advantages

- High degree of automation: The automatic powder coating line uses advanced automation technology to achieve automatic powder spraying, automatic cleaning, automatic recycling and automatic curing process steps to improve production efficiency and coating quality.

- Accurate coating control: Equipped with an advanced coating control system, it is able to precisely control the powder spraying volume, spraying speed and spraying pattern to ensure uniform and consistent coating quality.

- Reliable quality control: Equipped with an advanced quality control system that monitors and adjusts coating parameters in real time to ensure the quality and consistency of the coating.

- Environmentally friendly and energy saving: solvent-free and VOC-free powder coatings are used to reduce environmental pollution. Equipped with an efficient powder recycling system to reduce powder waste and resource consumption.

Product images

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of powder coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.