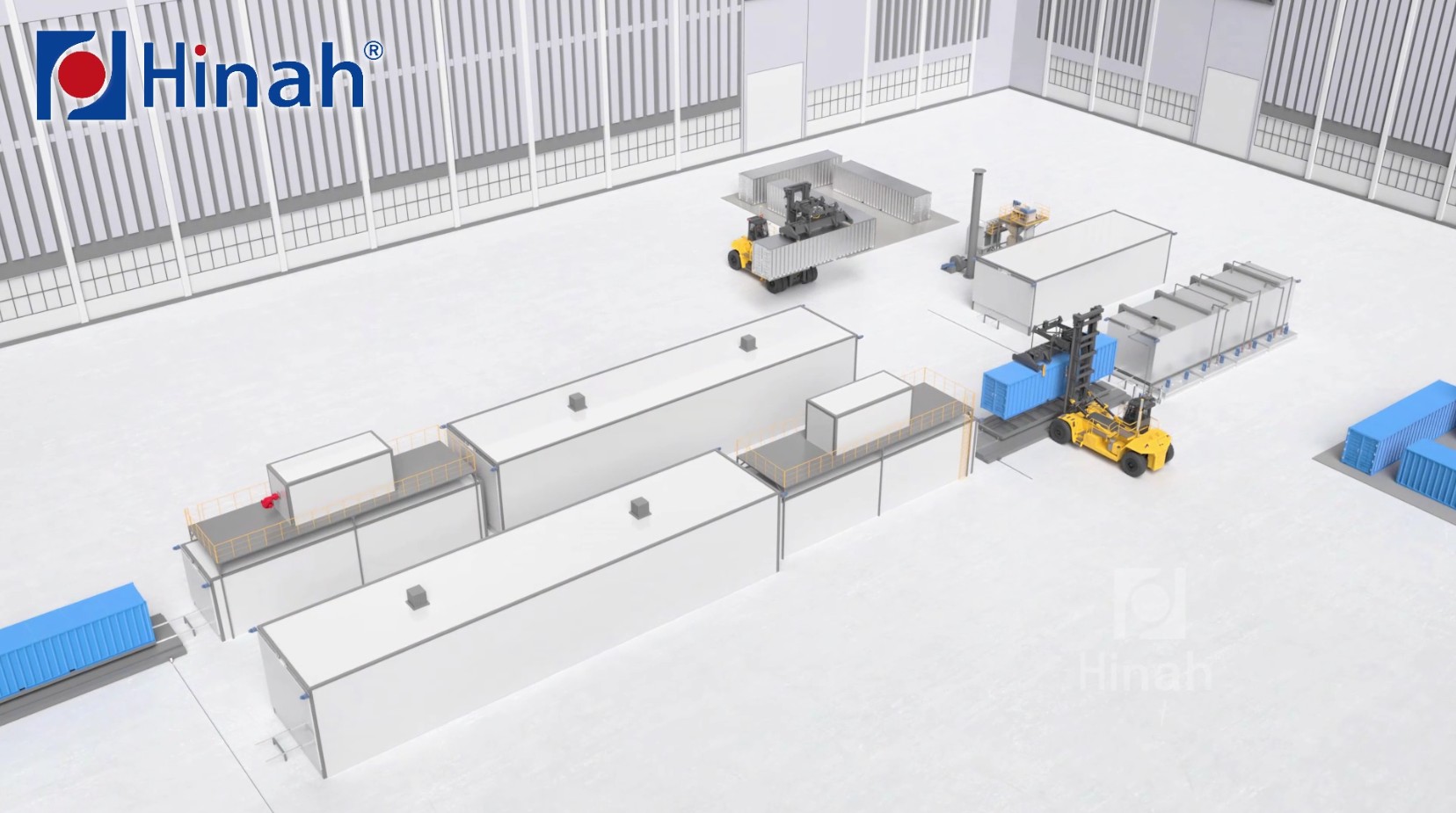

liquid coating line

Precision Engineered for Peak Performance

Ideal for high-volume production or intricate surface treatments, our liquid coating line ensures seamless application and cost-efficiency while maintaining exceptional durability. Engineered for versatile performance, these systems enable operators to achieve uniform, high-gloss finishes on a wide range of materials, including metals, plastics, and composites. With customizable spray parameters and rapid-drying formulations, they’re tailored for facilities seeking scalability, fast turnaround times, and adaptability to diverse project demands.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

benefits of liquid coating line

- Versatility:

Liquid coating lines can be adapted to a wide range of substrates and coating types. - Customization:

They offer a high degree of customization in terms of colors, effects, and surface finishes. - Efficiency:

Automated liquid coating lines can be highly efficient, with the capacity to process large quantities of items. - Quality Control:

These lines often incorporate quality control measures to ensure consistent and high-quality finishes.

Industries Using Liquid Coating Line

- Automotive: For painting vehicles and components.

- Manufacturing: For coating metal parts, plastic components, and other items.

- Furniture: For applying finishes to wooden furniture and kitchen fronts.

- Construction: For protecting metal structures and applying finishes to building components.

- Consumer Goods: For applying finishes to various products like appliances, electronics, and consumer items.

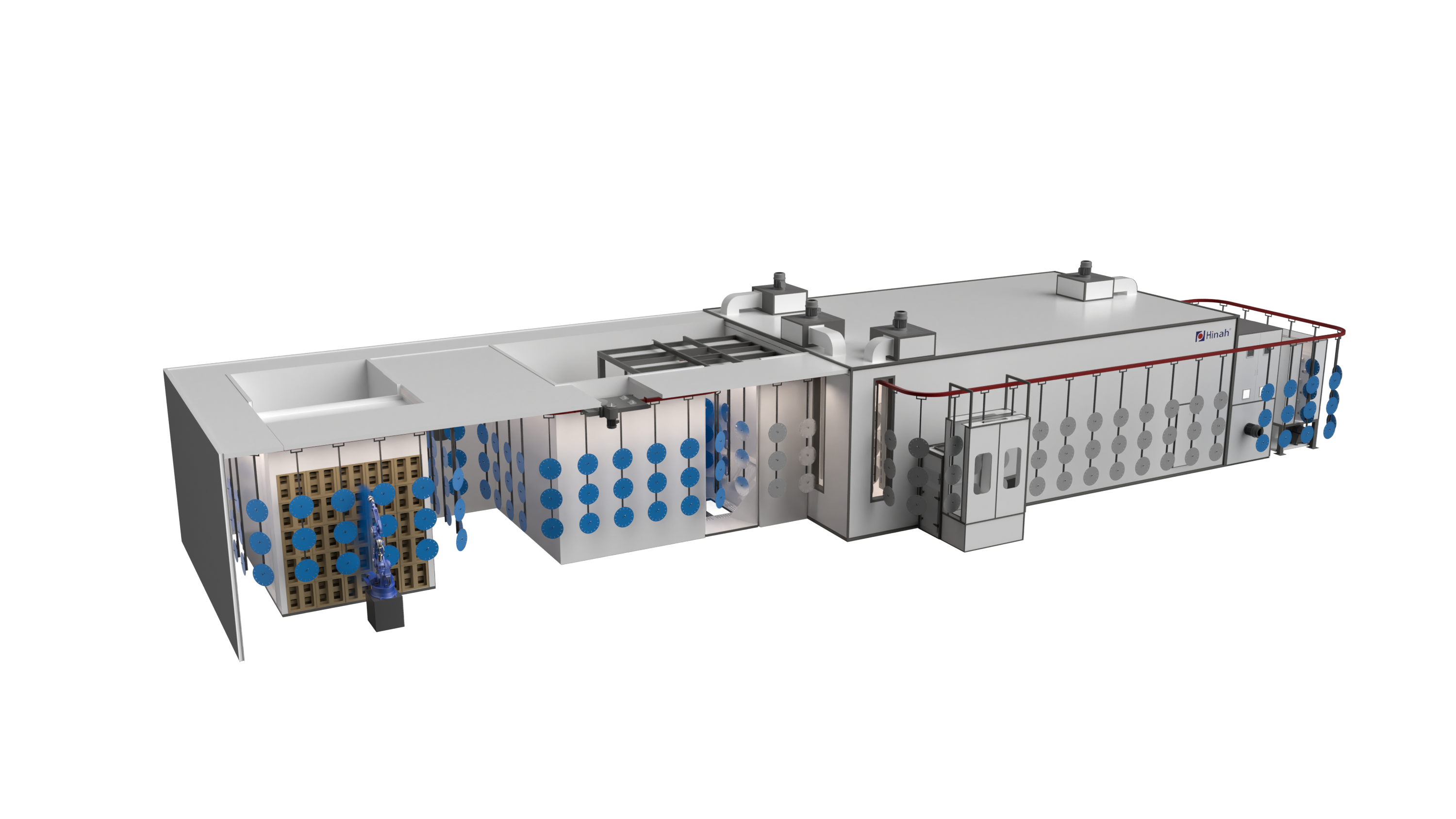

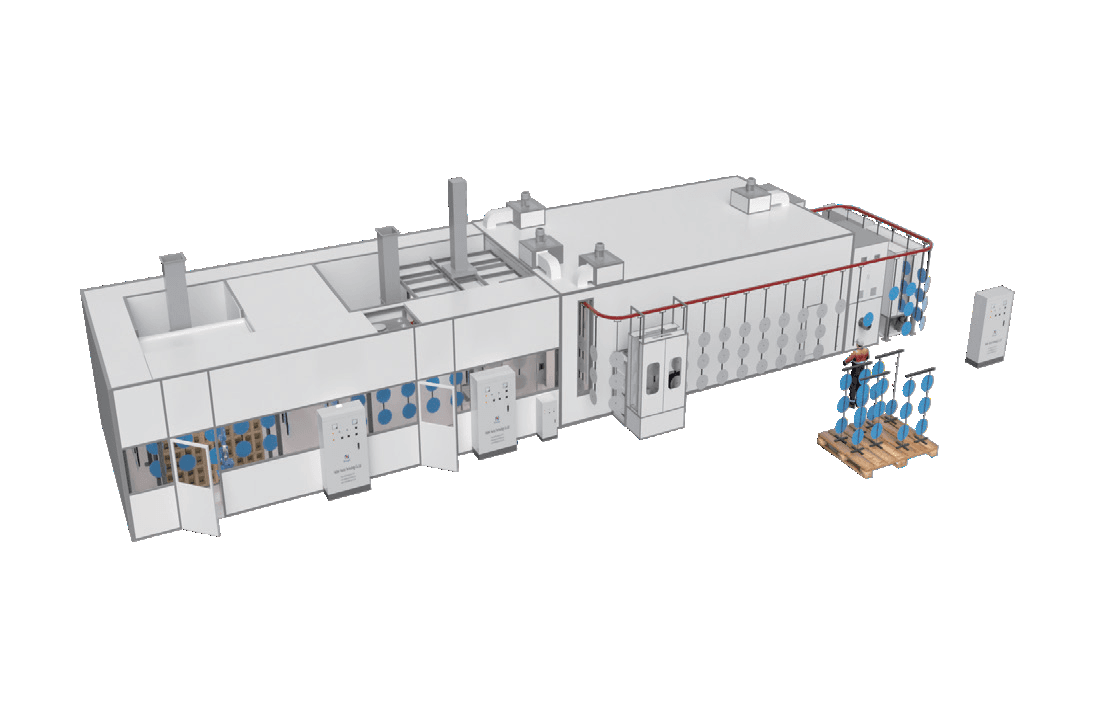

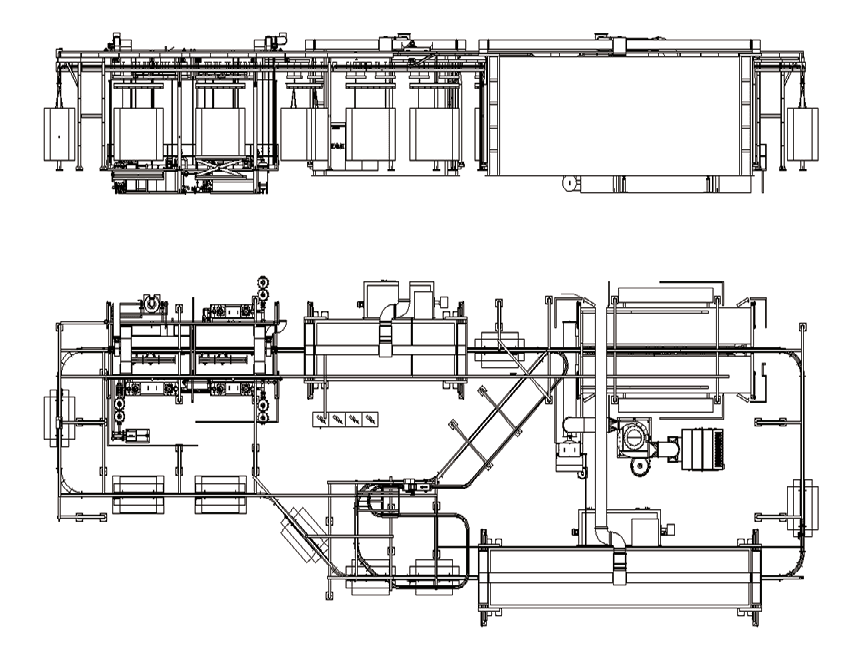

Components of liquid coating line

1. Workpiece Dust Removal System: Cleans surfaces of workpieces before coating to eliminate dust, debris, or contaminants, ensuring optimal adhesion and finish quality.

2. Drying Furnace System: Preheats or dries workpieces to remove moisture or solvents, preparing them for subsequent coating or curing stages under controlled temperatures.

3. Ω Spray Painting Room: A sealed booth for manual or automated spray application of liquid coatings, equipped with ventilation to filter overspray and maintain air quality.

4. Robot Spraying Room: Utilizes programmable robotic arms for precise, consistent coating application, enhancing efficiency and reducing waste on complex geometries.

5. Flash Drying Room: Accelerates solvent evaporation from freshly applied coatings using mild heat or airflow, creating a tack-free surface before curing.

6. Curing Furnace System: Applies high heat to chemically cure coatings, ensuring durability, hardness, and resistance to environmental factors.

7. Forced Cooling Room: Rapidly lowers workpiece temperatures post-curing using fans or chillers to stabilize coatings and prepare for handling or packaging.

8. Conveyor Chain: Automates material handling by transporting workpieces sequentially through all stages of the coating line, maintaining process continuity.

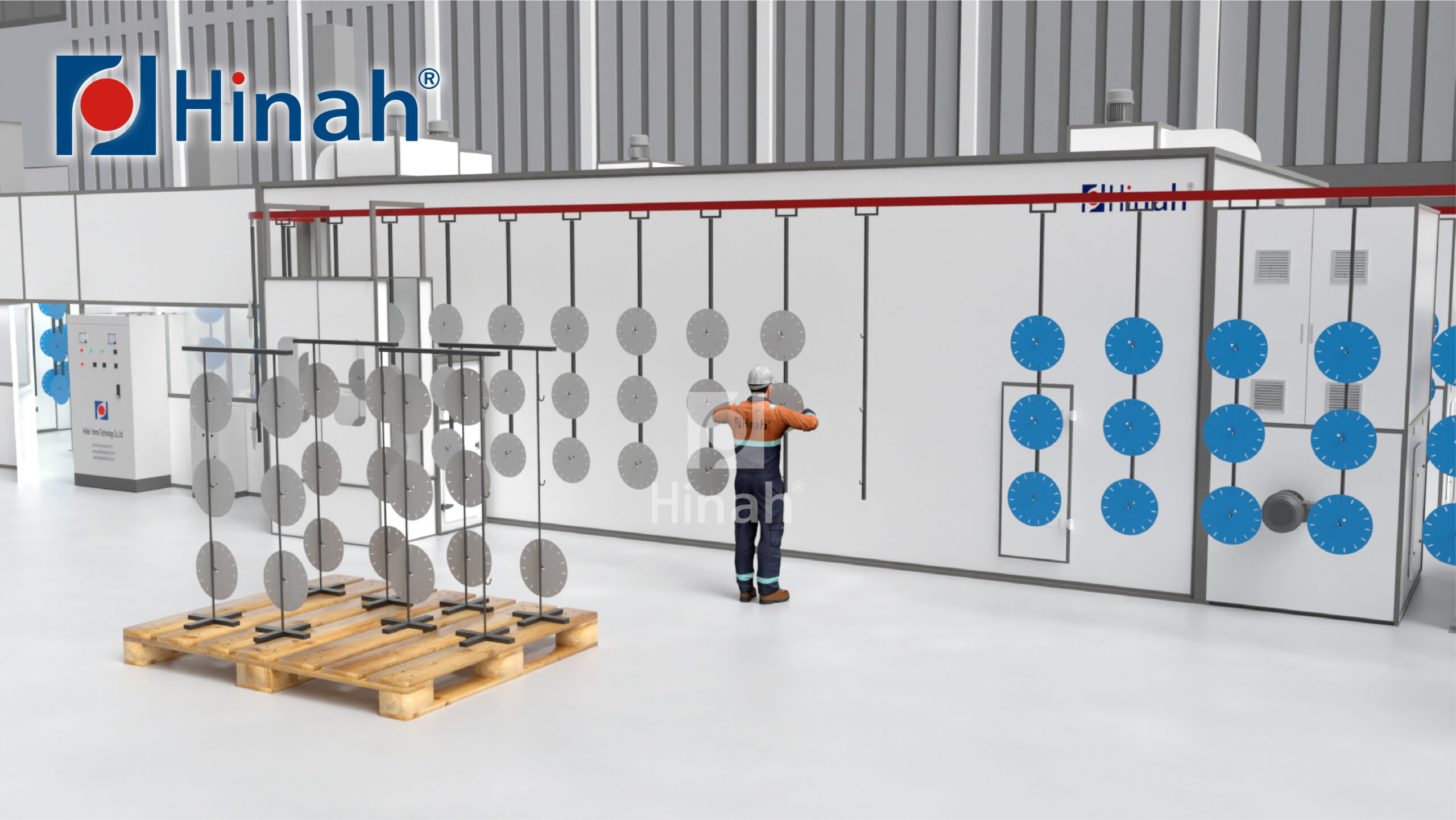

Case Show

liquid coating line for diamond saw blades

Our advanced liquid coating system revolutionizes surface treatment for diamond saw blade manufacturing. This automated line features precision-controlled spray nozzles and optimized viscosity management, ensuring uniform coating application across irregular blade surfaces. The integrated IR-curing tunnel achieves rapid polymerization while maintaining coating integrity at high temperatures. With 23% increased production efficiency and 15% material savings compared to traditional methods, this solution helps manufacturers enhance product durability and corrosion resistance – critical for extending cutting tool lifespan in harsh working environments.

Liquid coating line for ground rail

This custom-engineered coating system delivers exceptional corrosion protection for steel ground rails used in transportation and industrial applications. Our multi-stage pretreatment process ensures perfect surface preparation through alkaline degreasing and zinc phosphate conversion coating. The automated liquid painting system achieves 98% first-pass coverage on complex rail profiles, while the intelligent drying oven maintains consistent film thickness across 12-meter rail sections. With 40% faster processing speed than conventional dipping methods and 30% reduced paint consumption, this line helps infrastructure suppliers meet demanding project timelines without compromising on coating quality.

Competitive Advantages

- Versatility and Substrate Compatibility: Suitable for diverse materials (metals, plastics, composites) and specialized coatings (anti-corrosive, UV-resistant), ensuring adaptability to industrial, automotive, or artistic applications.

- Color and Customization Options: Enables seamless color changes, gloss adjustments, and tailored finishes (e.g., matte, metallic) to meet precise aesthetic or functional requirements.

- Flexibility in Application: Manual or semi-automated processes allow quick adjustments to viscosity, layer thickness, and curing parameters, ideal for prototypes or low-volume batches.

- Ease of Masking: Simplifies partial coating by effortlessly masking non-target areas, reducing overspray waste and ensuring clean edges for complex designs

Product images

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of painting line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.