products & capabilities

As a premier manufacturer of surface treatment technologies, we design and deliver industrial-grade equipment that drives efficiency across industries. Backed by 30+ years of engineering expertise, our turnkey systems serve automotive, aerospace, shipbuilding and energy sectors with ISO-certified reliability. Discover how our patented technologies can optimize your surface finishing processes.Explore our robust portfolio of innovation-driven systems.

- Complete Coating Lines

- Automatic Powder Coating Line

- Manual Powder Coating Line

- Liquid Coating Line

- Powder Dip Coating Line

- E-coating Line

- Powder Coating Equipments&Systems

- Powder Coating (Painting) Robot

- Powder Coating Booth

- Powder Curing Oven

- Powder Coating Pretreatment System

- Powder Coating Conveyor System

- Electrical Control System

In addition, we are also equipped with other supporting facilities and products, such as environmental protection equipment.

Main Products

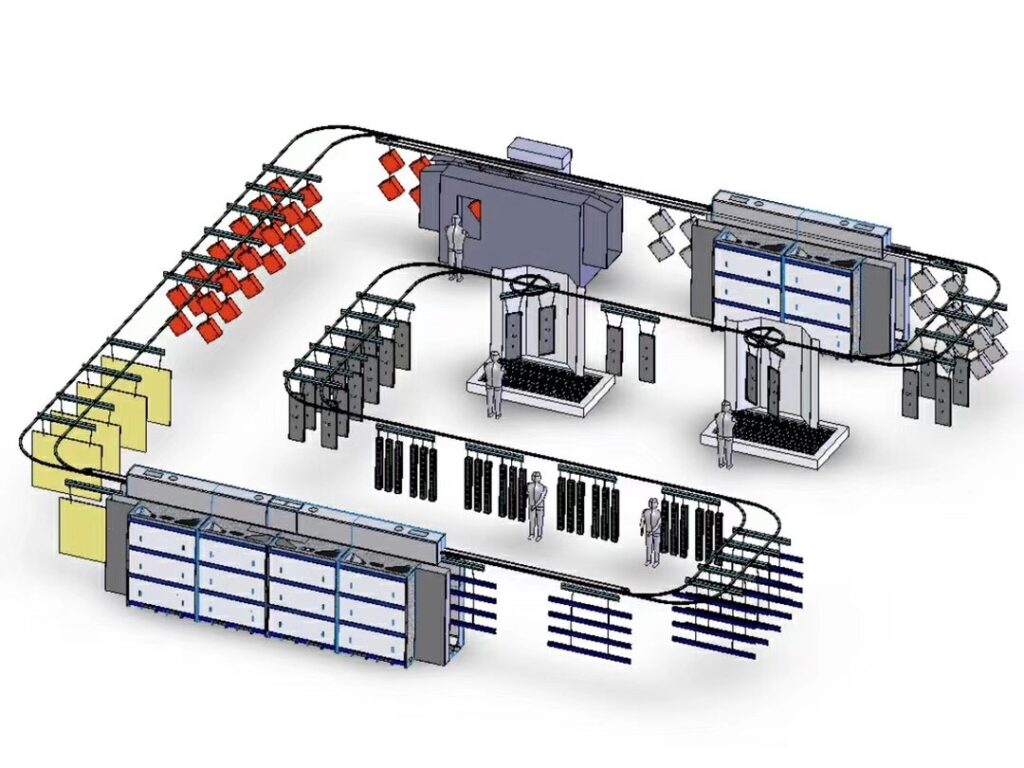

Automatic powder coating line

Completely automatic electrostatic powder coating lines with integrated automatic conveyor systems are capable of continuous work and beat-stepping under pre-set programs of the electronic control system. The customized system ensures efficient, energy-saving operation.

The efficient recycling system increases powder utilization to the limit and reduces costs.

-1-1024x768.jpg)

Manual powder coating line

Semi-automatic electrostatic powder coating lines are equipped with manual conveying lines.

This greatly improves production efficiency. Semi-automatic electrostatic powder coating lines have better compatibility with a wide range of workpieces and can be put into production with only a slight change in the hangers. It is the best choice for small and medium sized powder coating plants.

Liquid coating line

Fully automatic liquid paint spraying lines are suitable for a very wide range of applications, whether it is an orbital paint dipping line or a plastic dipping line, and can achieve fast spraying. Together with the fully automatic paint spraying robot, it can achieve a higher automation effect, reduce pollution, and lower production costs.

Powder Dipping coating line

The dip tank type electrostatic powder coating line uses electrostatic powder fluidized bed technology, which has very good coating speed and coating effect for valves, pipe fittings, and other complex-shaped equipment. The fluidized bed dipping method can ensure the uniformity of the surface coating. The fully automated dipping powder coating line has high coating efficiency and good compatibility.

E-coating line

The electrophoretic coating line can achieve all-round, uniform, and dead-angle-free coating of the workpiece, which is especially suitable for complex-shaped workpieces, such as automobile bodies and hardware parts, providing high-quality coating film with good adhesion, corrosion resistance, wear resistance, and weather resistance, ensuring the workpiece’s service life and beauty.

NEED HELP NOW?

Our coating line experts guarantee response within 4 hours and customized solutions within 24 hours. With 30+ years of industry-specific experience, we’ll diagnose your line issues and deliver fast-track improvements – guaranteed compliance with international coating standards.

More Products

powder coating equipment & systems

Powder Coating Robot

Powder Coating Booth

Powder Coating Curing Oven

Pretreatment System

Conveyor System

Electrical Control System

How to order?

Powder Coating line Order & Finish Process

HANNA Technology’s strong technical team can provide the most reasonable design and solutions:

- Customized design. Customized design solutions can meet customer needs efficiently and economically.

- Advanced technology with high availability. HANNA Technology continues to develop and improve existing equipment, and these technical advantages can provide customers with more efficient, advanced, and environmentally friendly coating solutions.

- Over 30 years of experience. HANNA Technology has rich experience and practice in the design and production of powder coating lines, and can provide professional technical guidance and suggestions to avoid problems and improve production efficiency and product quality.

- Reasonable construction cost. HANNA Technology gathers the advantages of the local industrial chain and can provide customers with more reasonable prices for solutions.

01

inquiry and quotation

The customer’s message will be answered within 24 hours.

You can learn about HANNA’s powder coating line, and you can request catalogs, technical parameters, quotations, etc.

HANNA will provide graphic design drawings and overall solutions according to the client’s needs, and mutually determine the solution that matches the customer’s needs.

02

Design solution & sign contract

HANNA’s technical team will provide a very detailed design plan, including a layout plan, process flow diagram, equipment list, equipment parameters, equipment price, etc.

Ensure a reasonableness, high efficiency, and energy-saving plan. After the customer reviews and agrees to the solution, both parties agree and sign the sales contract.

03

payment and production

After the customer pays the advance payment or opens a letter of credit as agreed.

HANNA will make and complete the production plan according to the contract requirements, and carry out quality inspection of the powder coating line to ensure that it meets the contract and customer requirements.

04

delivery & after-sales

HANNA arranges packaging, transportation, and insurance for the powder coating line. After receiving, the installation and commissioning will be carried out, and after the commissioning is completed and put into operation.

HANNA provides technical support, troubleshooting, spare parts supply, etc.

FAQ

Powder coating lines are designed for applying protective and decorative polymer coatings to a wide range of metal products, including structural furniture, household appliances, automotive and agricultural machinery components, armored doors, commercial equipment, architectural aluminum profiles, and much more.

Powder coating is generally more durable and resistant to scratches than traditional paint, but it is not completely scratch-proof. While it can withstand significant wear and tear, scratches and other damage can still occur, especially under extreme conditions.

Liquid coatings offer certain benefits for effects and flexibility in substrate selection, whereas powder coatings offer efficiency, improved mechanical and durability properties and environmental friendliness.

Electrocoating, also known as e-coating, is a process that uses electrical current to deposit a paint coating onto a conductive metal part. This method is commonly used in industries like automotive and furniture to achieve uniform and durable finishes, especially for corrosion protection.

E-coating provides durable corrosion protection that can last for several years, depending on the environment and application. Its long-lasting nature is ideal for products exposed to harsh conditions, such as in the automotive industry, where parts need reliable resistance to moisture, salt spray, and chemicals.