Manual powder coating line

Precision Engineered for Peak Performance

Ideal for small-scale operations or specialty projects, our manual powder coating line delivers precision and affordability without compromising quality. Designed for hands-on control, these systems empower operators to achieve consistent finishes on complex or irregularly shaped parts. With modular components and easy-to-admit configurations, they’re perfect for workshops prioritizing flexibility, low upfront costs, and minimal training requirements.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

benefits of manual powder coating line

- Flexibility:

Manual lines are generally more flexible than automated lines, making them suitable for a wider range of part sizes, shapes, and production volumes. - Lower Initial Cost:

Manual lines typically have a lower initial investment compared to automated lines. - Good for Small to Medium Production:

They are well-suited for smaller workshops or businesses with moderate production needs.

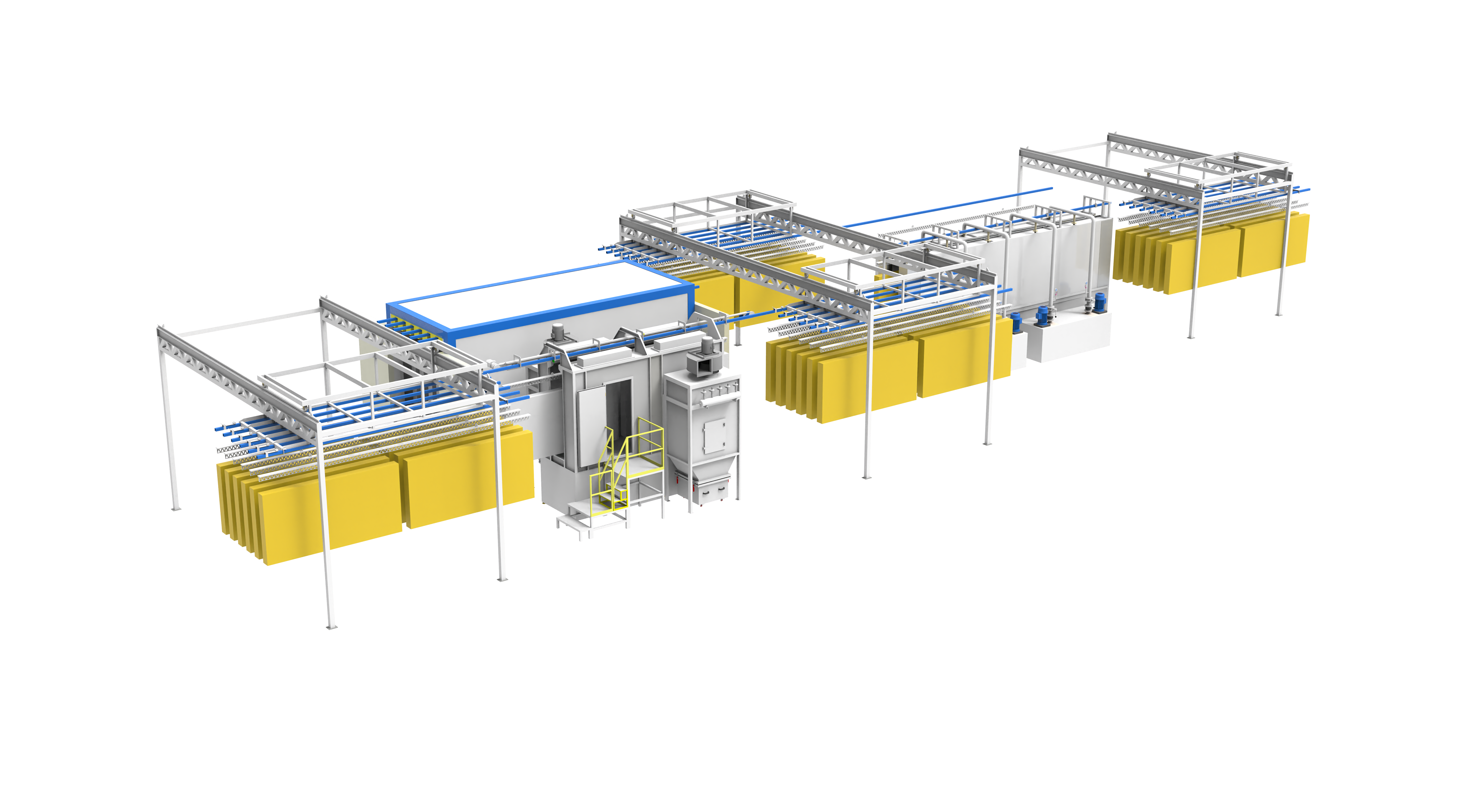

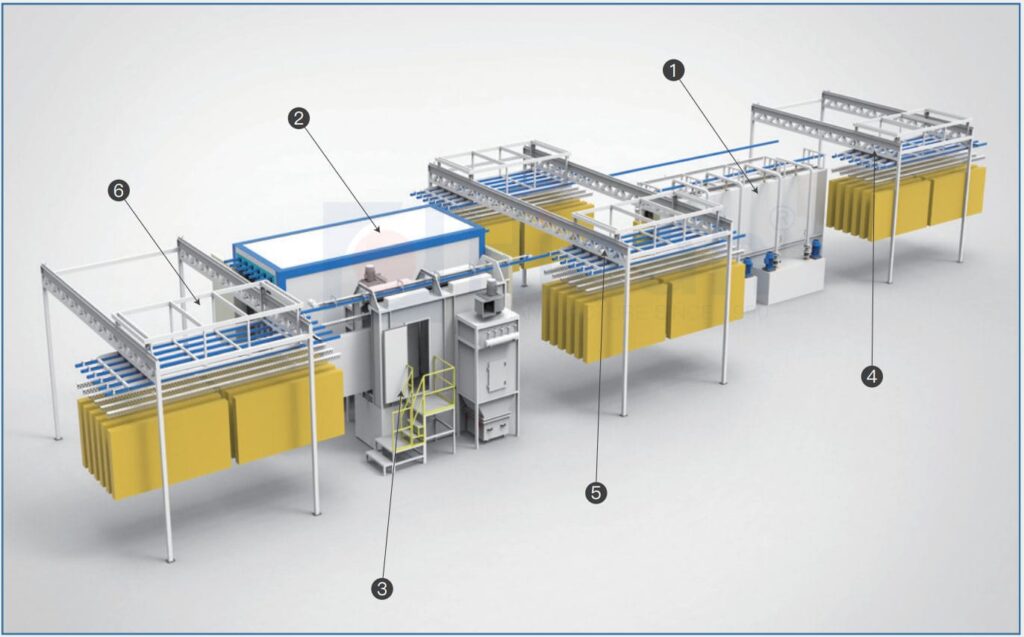

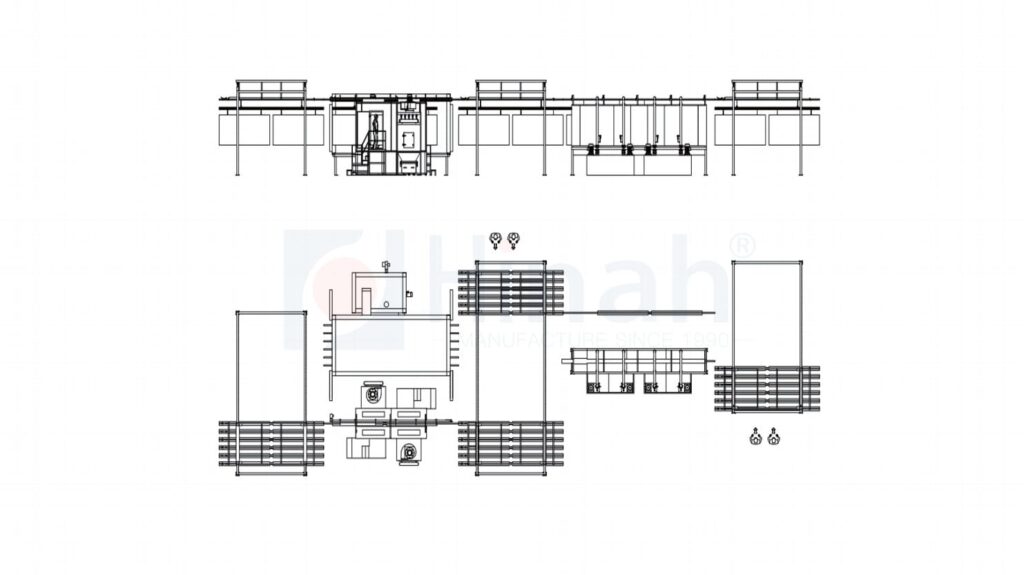

Components of manual powder coating line

1. Spray Pre-treatment: A preparatory stage where surfaces are cleaned and treated to ensure optimal adhesion of the powder coating, often involving degreasing or chemical processes.

2. Drying and Curing Furnace System: A heated chamber that dries the pre-treated surfaces and cures the applied powder coating, enhancing durability and finish quality.

3. Double Filter Powder Spray Room: An enclosed workspace equipped with dual filtration to efficiently capture overspray powder, maintaining a clean environment and reducing waste.

4. Loading Carriage: A manually operated platform or trolley used to load and position workpieces into the spray line for coating.

5. Transfer and Unloading Carriage: A mobile unit designed to transport coated workpieces between stations and safely unload them after the curing process.

6. Transfer Carriage: A simplified transport mechanism for moving workpieces between specific stages of the manual powder coating line.

Case Show

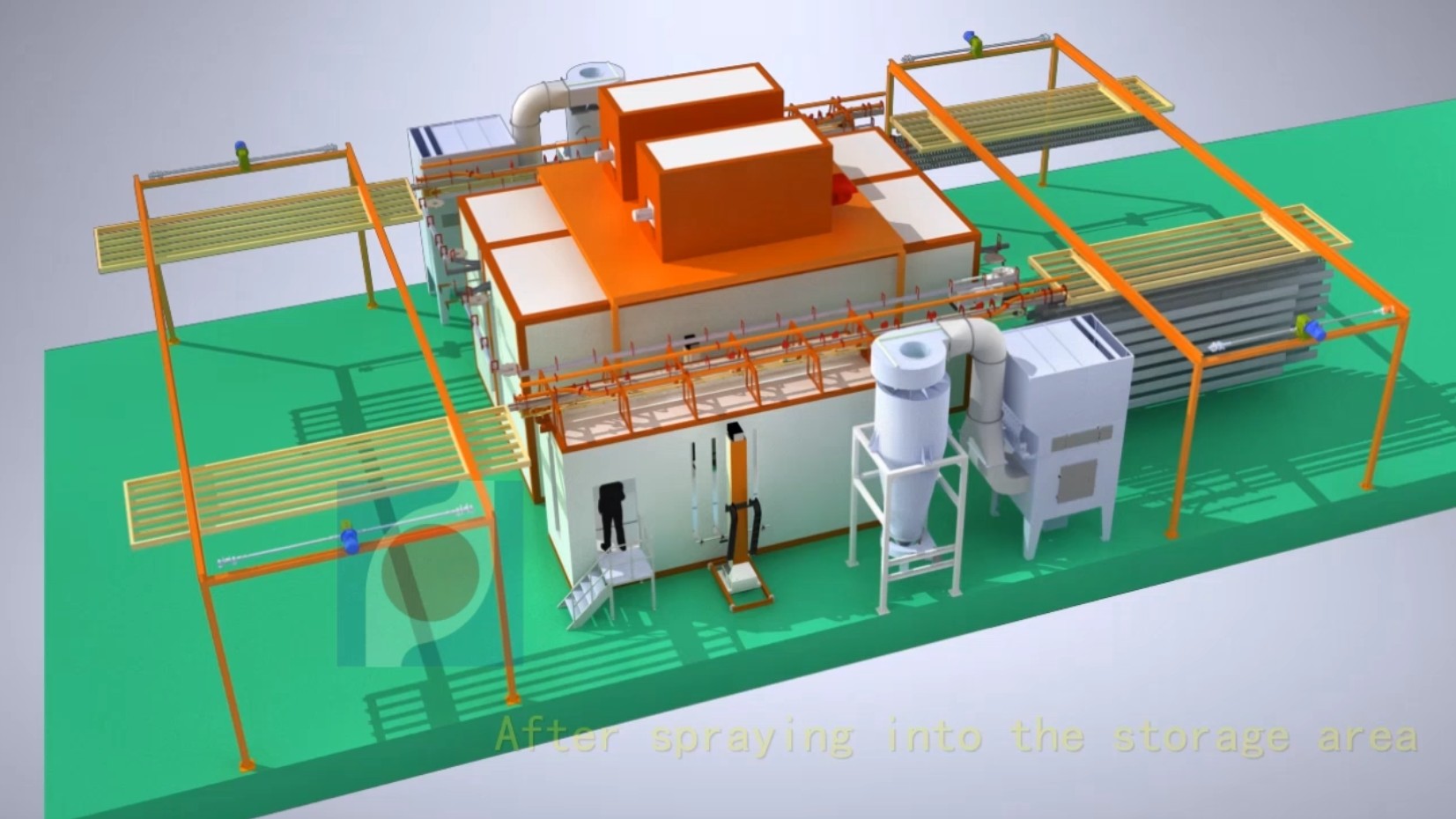

manual powder coating line for aluminium profiles

This is our specialized manual powder coating system engineered for aluminum extrusion applications. Featuring ergonomic rotating fixtures and electrostatic spray technology, the system achieves 360° uniform coverage on complex profiles including window frames, curtain wall components and heat sinks. The integrated curing oven maintains 180-200°C for perfect cross-linking, ensuring corrosion resistance exceeding 1,000 salt spray hours. Optional modular add-ons allow conversion to automated line as production scales. Ideal for metal fabricators seeking entry-level system with aerospace-grade finishing quality.

manual powder coating line for doors

Watch our manual powder coating process tailored for door production. The system incorporates 8-stage pretreatment (degreasing, phosphating, passivation) for optimal adhesion on steel/wood composite surfaces. Dual-axis reciprocating guns with digital flow control enable flawless finishes in woodgrain, metallic or textured effects. Energy-recovery curing tunnel reduces power consumption by 35% compared to conventional ovens. Specialized jig system accommodates panel sizes from 600x2000mm to 1200x3000mm, perfect for both interior doors and security door manufacturers pursuing premium surface finishes with lean production setup.

Competitive Advantages

- Cost-Effective Investment: Lower initial setup and equipment costs compared to automated systems, making it ideal for small to medium businesses or budget-conscious operations. Simplified machinery reduces financial barriers to entry.

- High Flexibility for Customization: Enables easy adjustments to coating thickness, color changes, and complex geometries through direct operator control, catering to small-batch or customized production needs.

- Reduced Operational Complexity: Minimal reliance on advanced control systems or software, lowering maintenance expenses and technical training requirements. Operators can troubleshoot issues without specialized expertise.

- Scalable for Low-Volume Production: Optimized for short runs or prototype development, avoiding the need for large-scale automation. Manual operation ensures resource efficiency for projects with fluctuating demand.

Product images

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of powder coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.