Home » Products » Powder Coating Equipment » Powder Coating Booth

powder coating booth

Precision Engineered for Peak Performance

A powder coating booth is a specialized enclosure used for applying powder coatings to various products and surfaces. It provides a controlled environment for the powder application process, ensuring efficient and consistent coating while minimizing overspray and waste. These booths are essential for achieving high-quality powder coatings in both manual and automated applications.

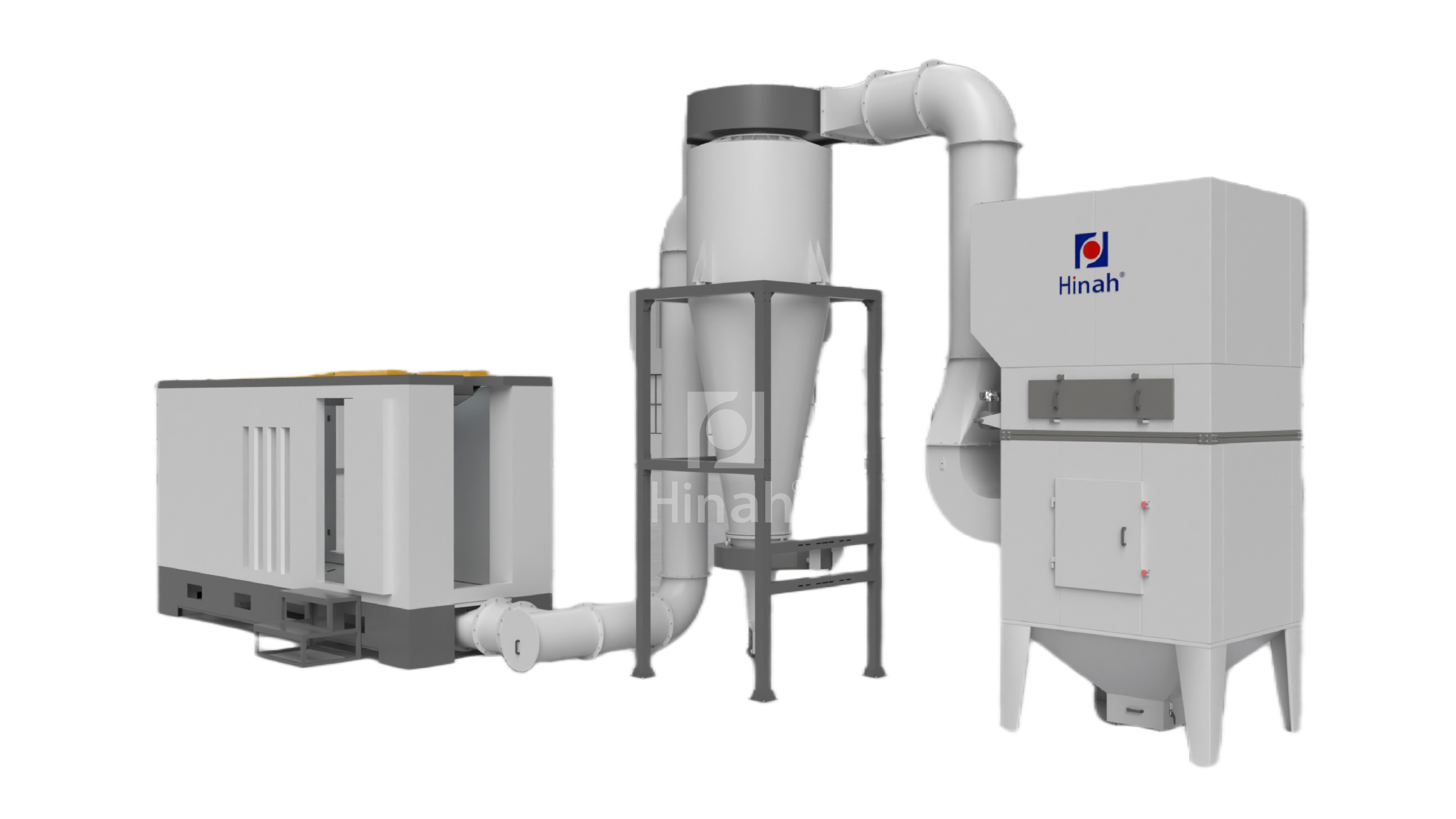

HANNA Technology has developed two types of high-efficiency powder coating booths – Fast Color Change Booth and Filter Recovery Booth – to meet the needs of different industrial scenarios.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

product details

type 1: Fast Color Change powder coating Booth

1. Sixth generation of intelligent spray gun, work on the groove of workpiece perfectly .

2. Fully consider color change system work, easy to clean,labour-saving.

3. All mechanical and electrical key parts to HANNA design are supplied by Top gun companies, such as Gema and Wagner, and that would ensure our machine work theoretically perfect.

4. Beautiful appearance, fine workmanship.

Working Principle:

The powder is automatically transported from powder supply center to electrostatic spray gun driven by air power source;The electrostatic powder is partially sprayed onto the surface of workpiece; Part of the powder flow through to the large cyclone recovery device and secondary recovery unit; A small amount remains in the inner wall of spray booth. Part of the powder passes through the air suction cyclone, go through primary recovery unit and bottom vibrating screen, then flow back to the powder supply center driven by the powder recovery pump. Part of the powder drive by rotation movement on the top part of the large cyclone and flow into the secondary recovery unit, then go through the rotary wing filter and left in the powder collecting bucket at the end.

Characteristics of Fast Color Change Booth:

- No dust spill out, Minimum powder waste

- Quick color change (10-15 minutes automated color change), Multi-color change design

- Powder Recovery Efficiency high as 99.2%

type 2: Filter Recovery Powder Coating Booth

1. Equipped with high-efficiency cartridge filter system, ensures clean working environment and efficient powder recovery.

2. Simple and compact design, easy to operate and maintain, ideal for small-batch and frequent color change production.

3. All electrical and mechanical components are from leading brands, ensuring long-term stable operation.

4. Modular booth structure, convenient for assembly and future expansion.

Working Principle:

The powder is delivered from the powder supply center to the electrostatic spray gun by air pressure. During spraying, excess powder is drawn into the recovery system by negative pressure airflow. The powder passes through pre-filtration zones and is then captured by high-performance filter cartridges. The filtered air is discharged back into the workshop after purification, while the collected powder falls into the recovery bucket below through automatic pulse-jet cleaning. This ensures minimal powder loss and clean air circulation.

Characteristics of Filter Recovery Booth:

- No dust spill out

- Color change process (10-15 minutes manual work)

- Smart design, and easy to handle

- Safety and durability for sure

- Outstanding appearance and fine workmanship

- Shorten your labor into one-man operation

product functions

- Overspray Collection:

They are equipped with systems to collect overspray, which includes a recovery system that often uses a fan to pull air through the booth and capture the powder. - Air Filtration:

Filter systems are used to clean the air, removing the powder particles and ensuring a clean environment for the operator. - Airflow Management:

Some booths use downdraft designs or other airflow systems to optimize powder application and containment.

product video

Competitive Advantages

- Enhanced Contamination Control: Powder coating booths feature advanced filtration systems and sealed environments, achieving over 98% airborne particle removal. Consistent negative pressure ensures minimal cross-contamination, delivering flawless finishes even in high-volume production settings.

- Optimized Airflow Dynamics: Precision-engineered airflow patterns enable uniform powder distribution across intricate geometries. Adjustable ventilation settings eliminate turbulence, reducing rework rates by up to 30% while maintaining operator comfort.

- Modular Scalability: Booths support flexible configurations for diverse part sizes and production scales. Rapid-change cartridge filters and expandable enclosures reduce downtime by 50%, adapting seamlessly to batch or continuous workflows.

- Advanced Clean Air Systems: Powder coating booths use high-efficiency air filters and sealed designs to capture 98% of dust and particles. Controlled airflow keeps the workspace clean, ensuring smooth finishes without contamination risks.

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.