Home » Products » Powder Coating Equipment » Powder Curing Oven

powder curing oven

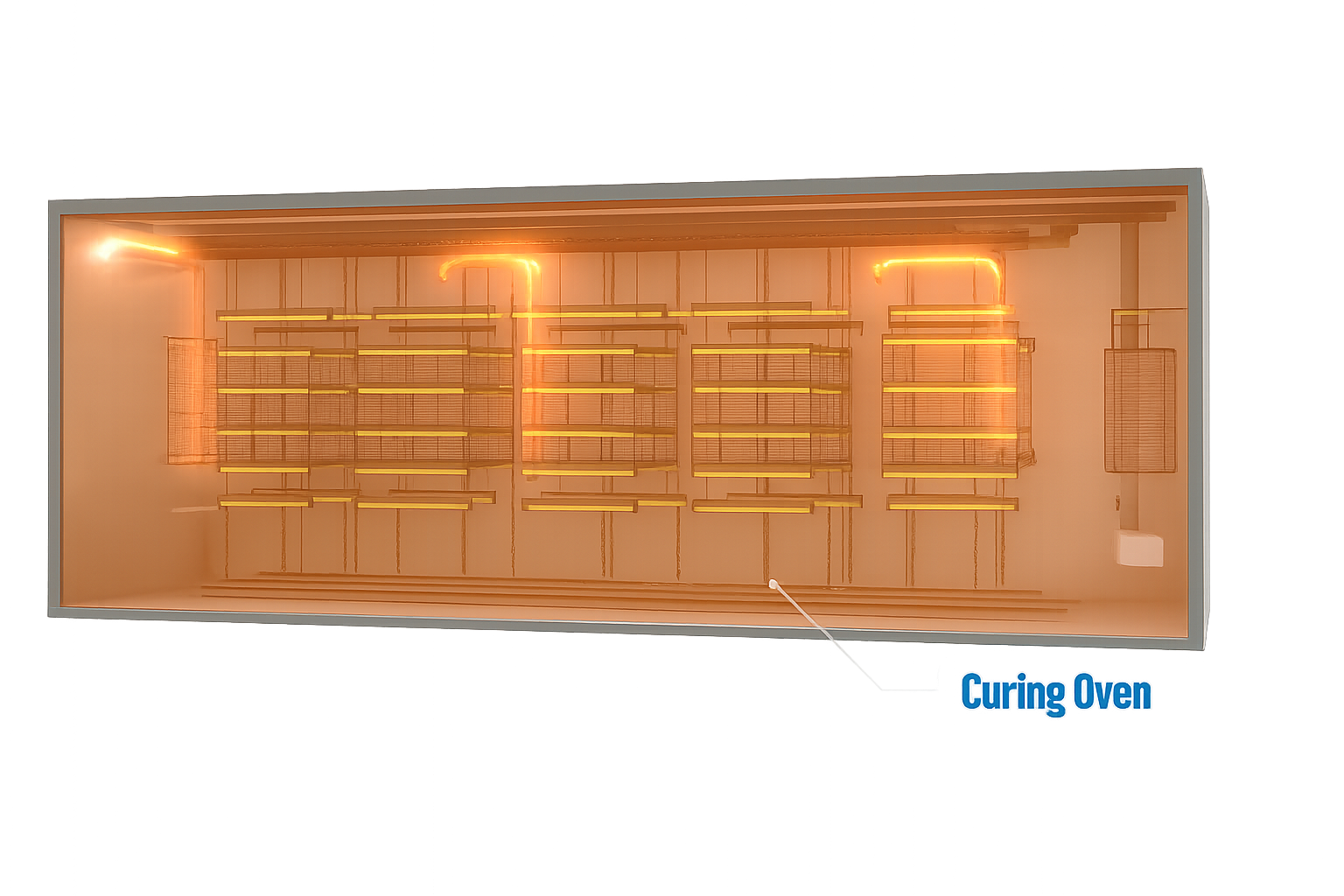

Precision Engineered for Peak Performance

A powder coating oven is an essential component in the powder coating process, designed to cure applied powder coatings into a durable, smooth, and uniform finish after the powder is electrostatically applied in the coating booth. By using controlled heat to melt and fuse the powder particles, the oven creates a resilient protective layer that adheres seamlessly to the substrate, with precise temperature uniformity and airflow ensuring optimal curing conditions across various materials and coating types. These ovens feature rapid heating cycles and customizable configurations, enabling high-volume operations and consistent, high-quality results with minimal environmental impact, ultimately forming a complete, efficient system alongside powder coating booths to achieve superior surface finishes and long-lasting corrosion resistance.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

product details

type 1: Camel Back Curing Oven

Talk about bridge type curing oven, the structure get perfectly functional design on thermal insulation, and hot air flowing around the top zone will not have convection with cold air outside, which offer lower energy consumption. This design is more suitable for wide workpiece but longer one. Usually, when we have a bridge type curing oven, the longer the workpiece, the larger the turning radius will be. More height the workpieces have, conveyer track and drying path would be relative higher to the ground, and that would make more difficult design and construction costs.

Characteristics of Camel Back Curing Oven:

- High degree of safety, the heat source that links to the curing tunnel, will automatically ventilates first, then ignites to eliminate safety hazards.

- The structure of insulation board are made by technology like plug-in board,seamless docking, and thermal bridge transmission.

- Fuel oil burner type, rightful design on thermal ventilation syetem make air circulation reach a perfect balance which keep furnace temperature stabe.

- Gas burner type, heat 100% flow into the furnace, high efficiency, no waste.

type 2: Tunnel Curing Oven

Tunnel oven can be build up right on the flat ground, this work can be relatively cheaper than Camel Back Curing Oven, but reasonably weaker on thermal insulation because of heat convection. This design would be more suitable for long workpiece rather than wide one. if the opening of tunnel is too wide, the wind barrier will not be strong enough against heat convection, and that would make encourage heat loos, which slow down the oven heating up and increase power payment.

Characteristics of Tunnel Curing Oven:

- Power Mode:CNG/LPG/Diesel/Electric

- High Degree Of Safety

- Limited Heat loss With Air Curtain

- Uniform Temperature Within ±3℃

type 3: Batch Curing Oven

Gives significant double-panel design, door structure would go steel composition design by #16, 18 and 20 with rock wool insulation board plunged in, board density would not be selected less than 6#. The heating device adjusts the performance according to the PID fuzzy logic controller of the control panel. The heating unit uses a curved fan device to circulate air around through the powder coating oven to reduce fuel consumption. We also offer bearing components in wearing piece list, with significant feature against heat.

Characteristics of Batch Curing Oven:

- Gives optimal design to meet your need.

- With our proud workmanship, Hanna solution would hit your budget and factory capacity requirements perfectly.

- We optimize your system on dimensions by completely going through your workpiece weight, size, shape and the other factors.

- Excellent durability and reliability

- Gives low-maintenance design

- Smart design make it to drive

- Easy to handle loading and unloading operations, provide solutions for cargo handling of any size and weight.

product work process

- Object Preparation: The part is cleaned, pre-treated, and then coated with the desired powder.

- Oven Heating: The oven is preheated to the specified temperature.

- Curing Process: The coated object is placed inside the oven, and the heat causes the powder to melt, flow, and cure into a smooth, uniform coating.

- Cooling and Finishing: Once cured, the object is allowed to cool and then can be handled and shipped.

product video

Competitive Advantages

- Uniform and Stable Temperature Control: Advanced heating technology ensures consistent temperature distribution throughout the oven, eliminating localized overheating or underheating for reliable curing quality.

- Energy-Efficient Design: Optimized thermal systems and energy recovery mechanisms reduce energy consumption and operational costs while maintaining high efficiency.

- Quick and Flexible Production Adaptability: Supports diverse part sizes and materials, with rapid parameter adjustments to meet varying production needs, minimizing downtime and boosting productivity.

- Reliable and Easy-to-Maintain Structure: Modular components and smart monitoring systems simplify maintenance, extend equipment lifespan, and ensure uninterrupted production continuity.

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.