Home » Products » Powder Coating Equipment » Environmental Protection Equipment

Environmental Protection Equipment

Precision Engineered for Peak Performance

A powder coating conveyor system is an integrated solution designed to efficiently transport components through the entire coating process—from pretreatment and powder application to curing and cooling. Our systems prioritize precision, sustainability, and adaptability, featuring three conveyor configurations to suit varying production scales: automatic conveyor, power and free conveyor, and manual conveyor.

- All Processes Compliant with Global Standards

- 24/7 Technical Support & Rapid Response

- Optimized Performance for Long-Term Reliability

30+ Years

Industry Experience

1000+

Projects Delivered

24/7

Global Techinical Support

product details

type 1: Waste Water Treatment equipment

Wastewater Treatment Process Step

- Screening

Initial filtration captures solid debris, preventing downstream equipment damage while preparing wastewater for treatment. - Pumping

Efficient transfer system moves water through subsequent stages, maintaining consistent flow rates for uniform processing. - Aerating

Oxygen infusion activates biological breakdown, naturally decomposing dissolved contaminants in controlled environments. - Removing Sludge

Automated separation extracts concentrated solids, significantly reducing waste volume for eco-friendly disposal. - Removing Scum

Surface skimming eliminates floating residues, delivering clarified water ready for safe reuse or compliant discharge.

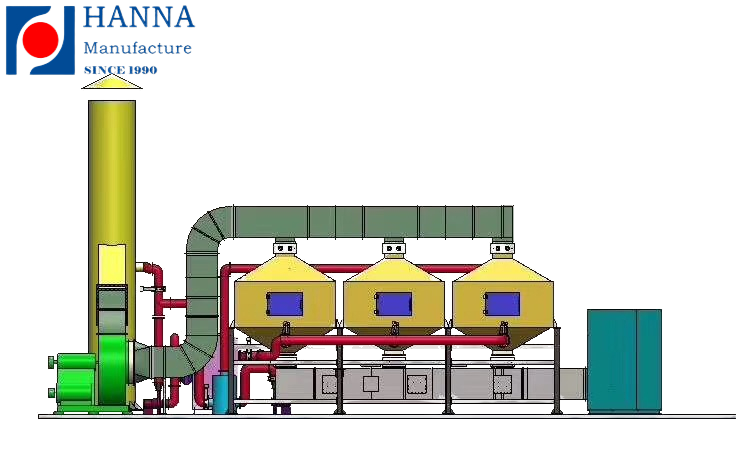

type 2: VOC Treatment equipment

Central Air Supply System

Precise Temperature & Humidity Control

Excellent Air filtration system to meet various air indications in the paint shop

Competitive Advantages

- Regulatory Compliance: Ensures adherence to environmental standards for wastewater discharge and air emissions, avoiding fines and legal risks.

- Resource Recovery: Enables water recycling and heat reclamation from exhaust streams, reducing utility costs and waste.

- Enhanced Safety: Eliminates exposure to toxic fumes and hazardous wastewater, protecting worker health and safety.

- Process Reliability: Prevents contamination of coating quality by maintaining clean air and water inputs consistently.

WHAT WE DO

- Expert Installation Teams

With 9 specialized teams, each averaging 5+ years of hands-on experience, we master every phase of coating line deployment. From electrical integration to calibration, our technicians ensure zero-error installations. Partner with us to eliminate trial runs – your production starts at full capacity within 48 hours of handover.

- Streamlined Process, Guaranteed Speed

Our certified workflow slashes installation time by 30% versus industry averages. Real-time progress tracking, pre-tested modular components, and parallel task execution mean your line transitions from blueprint to full operation in record time. Need rapid scaling? We’ve deployed 1000+ projects globally under 6-week deadlines.

- Timely Quotes & Clear Timelines

Precision meets transparency. Submit your specs through our online portal and receive a comprehensive quote within 72 hours, including 3D layout simulations. No hidden fees – our fixed-price contracts lock in costs upfront, while milestone-based scheduling gives you full visibility from Day 1.

- Your Project, Our Priority

At HANNA Coating, your order triggers an exclusive task force. Dedicated engineers, priority parts allocation, and weekly progress reviews ensure on-budget, on-schedule delivery. Whether retrofitting existing facilities or greenfield projects, we adapt to your floorplan constraints while maintaining ISO 9001 quality benchmarks.