Powder Coating vs. E Coating

E coating and powder coating are two widely used industrial finishing processes that provide protective and aesthetic coatings for metal parts in industries such as automotive, appliances, and manufacturing. Both methods enhance corrosion resistance, durability, and appearance, but they differ significantly in their application processes, benefits, and ideal use cases.

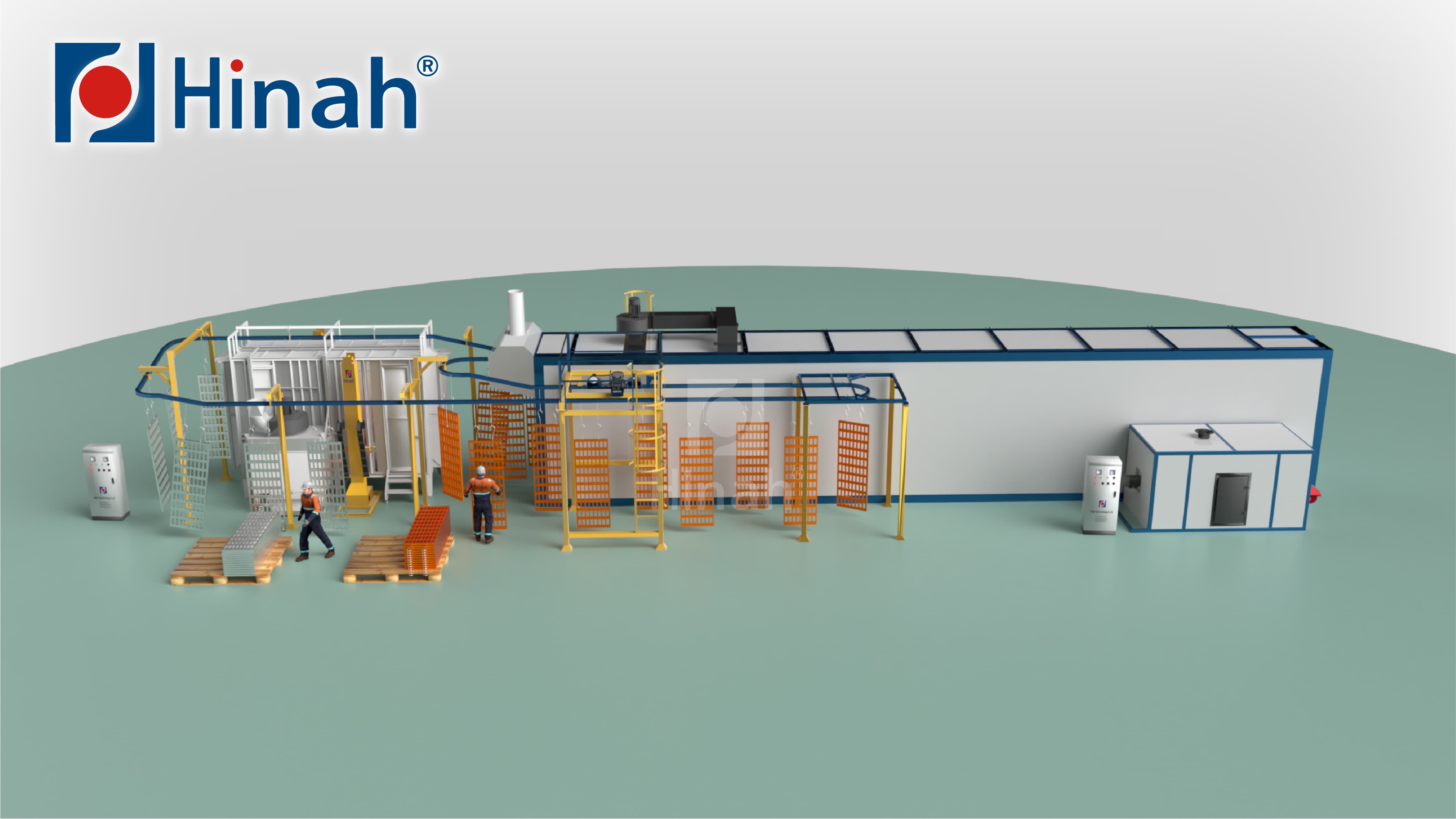

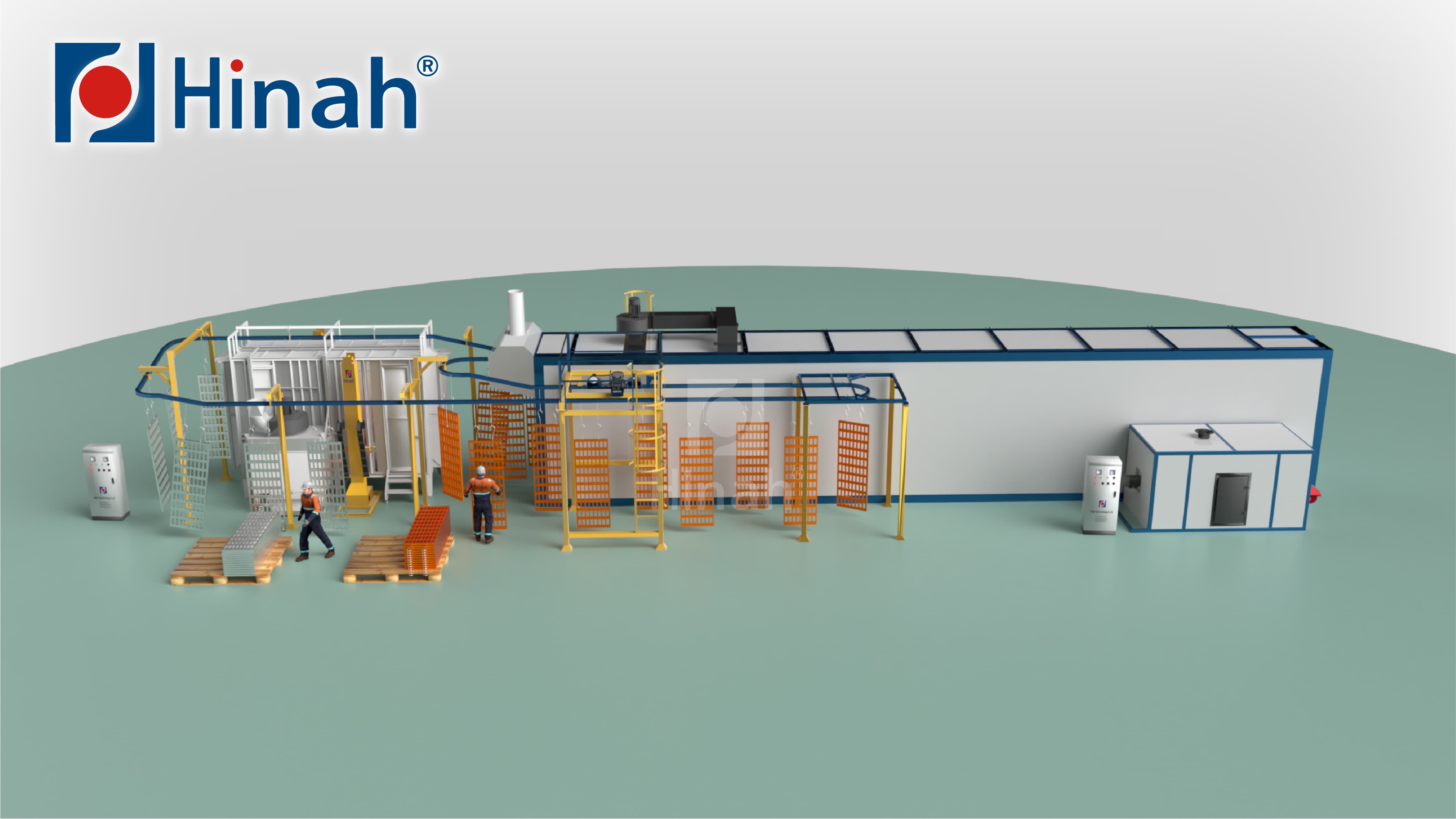

This article compares e coating and powder coating, drawing insights from industry experts to help businesses decide which process best suits their needs. As a leading powder coating plant manufacturer, Hebei Hanna Technology Co., Ltd. (Hinah) offers advanced coating systems, including powder coating booths and electrostatic spray guns, to deliver high quality finishes tailored to industrial requirements.

What is E Coating?

E coating, also known as electrocoating or electrophoretic deposition, is a wet finishing process that uses an electrically charged bath to deposit a uniform layer of paint or epoxy onto a metal substrate. The process involves submerging the part in a water based solution containing paint particles. An electric current attracts these particles to the metal surface, creating a thin, even coating. The part is then rinsed and cured in a powder coating curing oven to solidify the finish.

E coating is renowned for its ability to coat complex shapes and hard to reach areas, making it a preferred choice for parts requiring comprehensive coverage. Hinah's powder coating equipment supports e coating processes with advanced curing solutions for optimal results.

What is Powder Coating?

Powder coating is a dry finishing process that applies a free flowing, electrostatically charged powder to a metal surface, followed by curing to form a durable, protective layer. The powder, typically composed of epoxy or polyester resins, pigments, and curing agents, is sprayed onto the grounded part using an electrostatic spray gun in a powder coating booth.

The charged particles adhere to the surface, and the part is then cured in a powder coating curing oven at high temperatures (190 210°C) to melt the powder into a smooth, hard finish. Powder coating is valued for its thick, durable coatings and aesthetic versatility. Hinah’s powder coating systems, including powder coating conveyors, ensure efficient and consistent application for high volume production.

E Coating vs Powder Coating in Processes?

The processes for e coating and powder coating differ in their application methods, material usage, and coating characteristics.

E Coating Process: In e coating, the metal part is submerged in a bath of water based paint or epoxy. An electric current is applied, causing the charged paint particles to deposit uniformly onto the part’s surface.

The immersion method ensures even coverage, including recesses and intricate geometries. After coating, the part is rinsed to remove excess solution and cured in a powder coating curing oven to cross link the coating, forming a corrosion resistant finish. This wet process is highly controlled, allowing precise regulation of coating thickness. Hinah’s coating equipment supports e coating with advanced pretreatment and curing systems for consistent quality.

Powder Coating Process: In powder coating, a dry powder is applied using an electrostatic spray gun in a powder coating booth. The powder particles, charged electrostatically, adhere to the grounded metal surface. The part is then cured in a powder coating curing oven, where the powder melts and forms a thick, durable coating. This dry process eliminates the need for solvents, reducing waste and VOC emissions.

Hinah’s powder coating systems integrate powder coating conveyors for automated, high efficiency application, ideal for large scale operations.

What Are the Key Advantages of Each System?

Both e coating and powder coating offer unique benefits, making them suitable for different applications.

E Coating Advantages:

Uniform Coverage: E coating excels at coating complex shapes and hard to reach areas due to its immersion process, ensuring comprehensive protection.

Corrosion Resistance: E coatings provide superior corrosion resistance, making them ideal as primers for automotive and marine applications.

Thin Coating Control: The process allows precise regulation of coating thickness, producing thin, uniform layers (typically 10 30 microns) that minimize material usage.

Cost Effective for Intricate Parts: E coating line is economical for parts with complex geometries, reducing the need for manual touch ups.

Powder Coating Advantages:

Durability: Powder coating produces thick, robust coatings (50 100 microns) that resist chipping, scratching, and wear, ideal for high traffic or outdoor applications.

Aesthetic Versatility: Available in a wide range of colors, textures, and finishes (matte, gloss, textured), powder coating enhances visual appeal.

Eco Friendly: The process produces minimal VOCs and allows overspray to be recycled, reducing waste and environmental impact.

UV Resistance: Powder coatings offer excellent protection against UV rays, making them suitable for outdoor products like furniture and architectural components.

What Are the Limitations of Each System?

Both systems have limitations that businesses must consider when choosing a coating solution.

E Coating Limitations:

Limited Color Options: E coating typically offers fewer color choices, often limited to black or neutral tones, making it less suitable for decorative applications.

UV Instability: Most e coatings are not UV stable, requiring a topcoat like powder coating for outdoor use to prevent fading.

High Initial Investment: Setting up an e coating facility requires significant investment in tanks, control systems, and curing equipment.

Bath Contamination Risk: The paint bath can become contaminated, affecting coating quality if not properly maintained.

Powder Coating Limitations:

Limited Coverage for Complex Parts: Powder coating struggles to reach deep recesses or intricate areas, potentially leaving uncoated spots.

Thicker Coatings: The process produces thicker coatings, which may not be suitable for applications requiring thin, precise layers.

Equipment Costs: While less complex than e coating, powder coating requires specialized electrostatic spray guns and powder coating booths, increasing setup costs.

Comparison Table: E Coating vs. Powder

Aspect | E-Coating | Powder Coating |

Application Method | Wet, immersion with electrostatic spray guns | Dry, sprayed with electrostatic spray guns in powder coating booths |

Coating Thickness | Thin (10-30 microns) | Thick (50-100 microns) |

Coverage | Excellent for complex shapes and hard-to-reach areas | Limited in recesses and intricate geometries |

Corrosion Resistance | Superior, ideal as a primer | Good, enhanced with primers |

UV Resistance | Poor, requires topcoat | Excellent, suitable for outdoor use |

Aesthetic Options | Limited colors and finishes | Wide range of colors, textures, and finishes |

Environmental Impact | Low VOCs, but bath maintenance required | Minimal VOCs, recyclable overspray |

Equipment | Tanks, powder coating curing ovens, control systems | Powder coating booths, electrostatic spray guns, powder coating conveyors, powder coating curing ovens |

How to Choose the Right Coating for Your Business?

Choosing between e coating and powder coating depends on your project requirements, budget, and application environment.

Part Complexity: For parts with intricate shapes or hard to reach areas, e coating is superior due to its immersion process, ensuring uniform coverage. Powder coating is better for simpler geometries where aesthetic appeal is a priority.

Durability Needs: If durability against physical wear or UV exposure is critical, powder coating is the better choice due to its thicker, more robust finish. For corrosion protection, e coating excels as a primer.

Aesthetic Requirements: Powder coating offers greater flexibility with colors and finishes, making it ideal for decorative applications like outdoor furniture or architectural elements. E coating is typically used for functional, non decorative purposes.

Budget and Scale: E coating requires higher initial investment but is cost effective for high volume, complex parts. Powder coating is more accessible for smaller operations but may incur higher material costs for custom colors.

Environmental Considerations: Both processes are eco friendly, but powder coating has an edge due to recyclable overspray and no risk of bath contamination.

Combining E Coating and Powder Coating: In many industries, such as automotive, e coating is used as a primer for corrosion resistance, followed by powder coating for durability and UV protection. This combination leverages the strengths of both processes, providing comprehensive protection and aesthetic appeal. Hinah’s coating systems support dual processes with integrated powder coating booths and powder coating curing ovens for seamless production.

Why Choose Hinah for Coating Solutions?

Hebei Hanna Technology Co., Ltd. (Hinah), a trusted powder coating plant manufacturer, offers a wide range of powder coating systems and industrial powder coating equipment, including powder coating booths, electrostatic spray guns, powder coating conveyor systems, and powder coating curing ovens. With a focus on innovation and quality, Hinah provides customizable solutions for both e coating and powder coating applications, ensuring efficiency and durability. Their competitive powder coating equipment cost and expert consultation help businesses achieve high quality finishes at cost effective rates.

Conclusion

The choice between e coating and powder coating depends on your project’s specific needs. E coating is ideal for complex parts requiring uniform, corrosion resistant primers, while powder coating excels in providing durable, UV resistant, and aesthetically versatile finishes. Combining both processes can offer the best of both worlds for demanding applications. Hebei Hanna Technology Co., Ltd. (Hinah) delivers advanced powder coating systems and coating equipment to support both methods, ensuring superior results tailored to your industry.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)