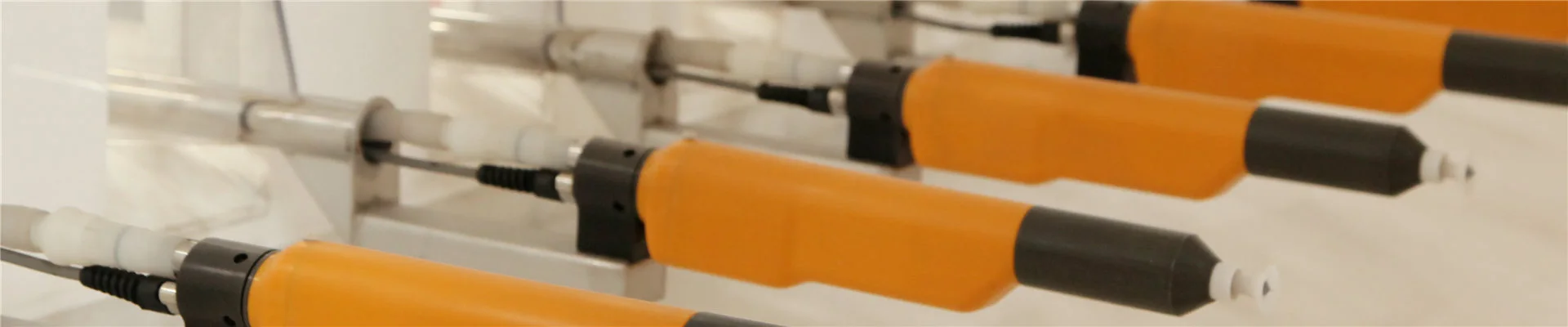

Filter Recovery Powder Coating Booth is an advanced system designed for efficient powder recovery and air filtration during the powder coating process. It uses high-efficiency filters to capture overspray particles, allowing them to be recycled and reused, reducing material waste. This booth is equipped with a self-cleaning feature, ensuring that filters maintain optimal performance without frequent manual maintenance. The system enhances productivity by improving powder utilization, reducing operational costs, and promoting a cleaner working environment. Ideal for industries like automotive and manufacturing, it ensures precise coating results while minimizing environmental impact.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)

.jpg)

.webp)