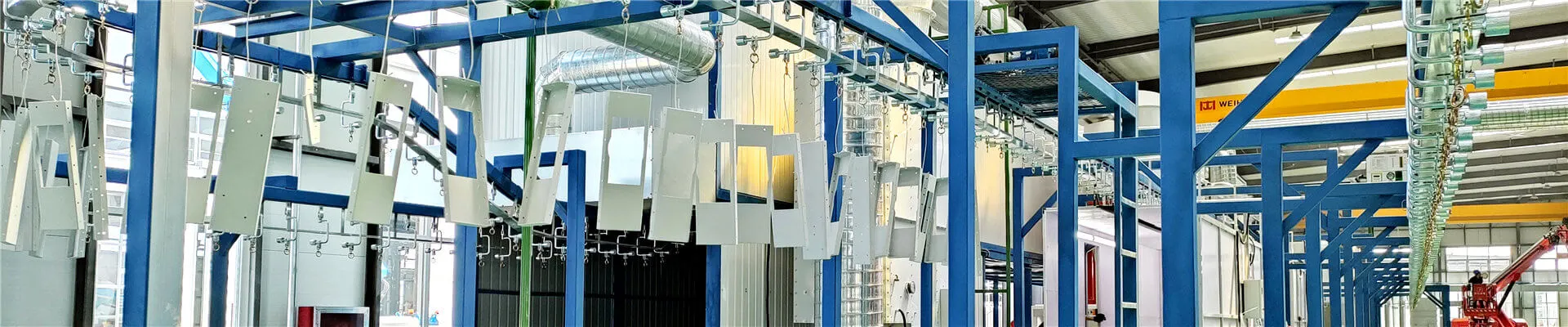

Powder coating control system is a crucial component in the powder coating process, ensuring consistent and high-quality finishes. It regulates various parameters such as voltage, current, air flow, and powder feed rate, which directly impact the coating’s uniformity and adhesion. The system typically includes a control panel with digital or analog displays for monitoring and adjusting settings. Advanced systems feature automated features like gun control, spray pattern adjustment, and diagnostics to optimize performance. With precise control, these systems enhance efficiency, reduce waste, and improve coating quality, making them essential in industries like automotive, aerospace, and manufacturing.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)