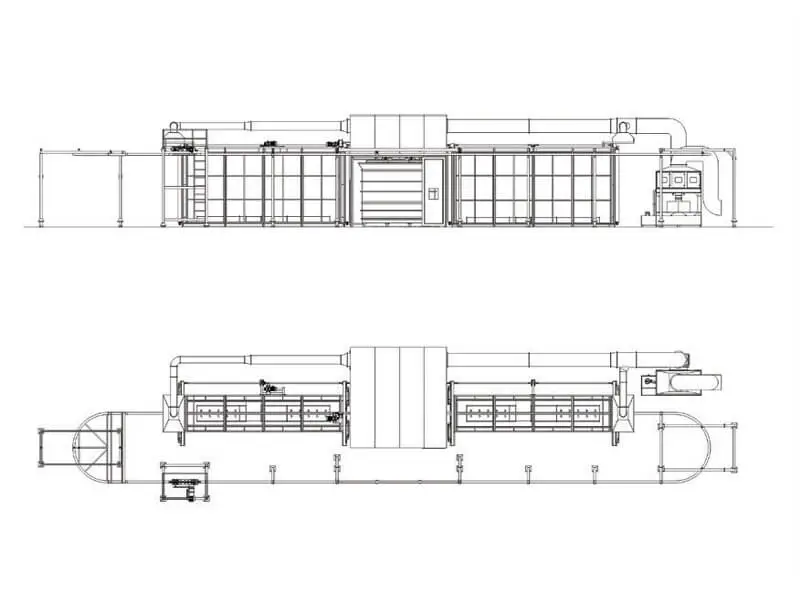

Powder Dip Coating Line offers numerous advantages, including enhanced coating uniformity and superior durability. This system is ideal for complex shapes and intricate parts, as it ensures consistent coverage without overspray. The automation reduces labor costs and minimizes human error, improving overall production efficiency. The customizable features allow the line to accommodate varying product sizes and materials, making it adaptable to different industries. Additionally, the powder dip coating process is environmentally friendly, with minimal waste and low energy consumption, making it a cost-effective and sustainable solution for high-quality finishes.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.jpg)

.webp)