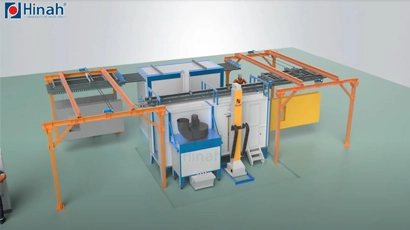

Manual powder coating line offers several advantages for businesses seeking flexibility and efficiency. With a wide range of configurations, it can be tailored to meet specific production needs. The line can be equipped with a non-powered overhead conveyor system, providing smooth and efficient material handling without requiring additional energy consumption. Additionally, customers can choose between a filter cartridge booth or a large cyclone powder recovery system, both designed to enhance powder utilization and reduce waste. This versatility ensures optimal coating quality, cost-efficiency, and adaptability for various production scales and requirements.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

_2.webp)

_2.webp)

_2.webp)

_2_20250225.webp)

.webp)