What is the Difference between Liquid Paint Coating and Powder Coating?

For manufacturers seeking durable, high-quality finishes, choosing between powder coating and liquid paint coating is critical. Hebei Hanna Technology Co., Ltd. (Hinah), a leading powder coating plant manufacturer, specializes in advanced surface treatment solutions. Understanding these technologies' core differences impacts your product quality, efficiency, and environmental compliance.

What are the Fundamental Process Differences?

Powder coating uses an electrostatic process. Electrically charged dry powder particles are sprayed onto a grounded metal surface. The component is then cured in a high-temperature powder coating curing oven, melting the powder into a continuous, hardened film. Crucially, no solvents are used.

Liquid paint coating relies on wet application (spraying, brushing, dipping). It requires solvents to keep pigments and resins in liquid form. These solvents evaporate during air drying or baking, releasing volatile organic compounds (VOCs). Achieving multiple coats often involves lengthy drying intervals.

How Do Durability and Finish Quality Compare?

Powder coating delivers superior mechanical and chemical resistance. The thermally bonded coating is thicker, more uniform, and less prone to chipping, scratching, or fading than liquid paint. It excels in harsh environments, protecting industrial equipment, automotive parts, and outdoor structures.

Liquid paint offers a wider range of special effects (like ultra-thin films or metallic flake) but is generally thinner and more susceptible to damage. Achieving consistent thickness on complex geometries is challenging, potentially leading to runs or sags. UV degradation is also a greater concern.

Which Process is More Environmentally Friendly?

Powder coating is inherently eco-friendly. It contains no solvents, eliminating hazardous VOC emissions during application. Overspray can often be collected (via advanced recovery systems in a powder coating booth and reused, minimizing waste – sometimes achieving near 100% transfer efficiency.

Liquid paint generates significant VOC emissions due to solvent evaporation. This requires expensive air scrubbers or incinerators to meet regulations. Overspray is typically unrecoverable, creating hazardous sludge waste requiring special disposal. Compliance costs are substantially higher.

What are the Cost and Efficiency Considerations?

Powder coating boasts higher long-term efficiency. Faster curing times in modern powder coating ovens allow quicker throughput. Reduced waste (reclaimable overspray) and lower environmental compliance costs contribute to a lower cost-per-part over time, especially for high-volume runs using automated powder coating conveyor systems.

Liquid paint has lower initial equipment costs for simple setups but higher operational expenses. Multiple coats and drying stages slow production. Costs for solvent handling, waste disposal, pollution control equipment, and compliance add up significantly. Touch-up and rework are also more frequent.

Which Applications Suit Each Technology Best?

Powder coating is ideal for:

Durable goods: Appliances powder coating equipment manufacturers, automotive wheels/parts, agricultural machinery, bicycles.

Architectural elements: Window frames, fencing, lighting fixtures.

Industrial components: Electrical enclosures, powder coating conveyor parts, shelving.

Any application requiring thick, tough, corrosion-resistant finishes.

Liquid paint is often chosen for:

Automotive body panels (requiring complex multi-layer effects).

Applications demanding ultra-thin films.

Certain temperature-sensitive substrates (some plastics, wood).

Very specialized aesthetic finishes difficult with powder.

What Equipment Defines a Modern Coating Line?

An automated powder coating line integrates key components:

Pre-treatment: Washers, chemical dips powder coating dip tank for cleaning and surface preparation.

Application Booth: Enclosed powder coating spray booth with electrostatic guns and efficient recovery systems.

Curing: High-efficiency powder coating oven for consistent film formation.

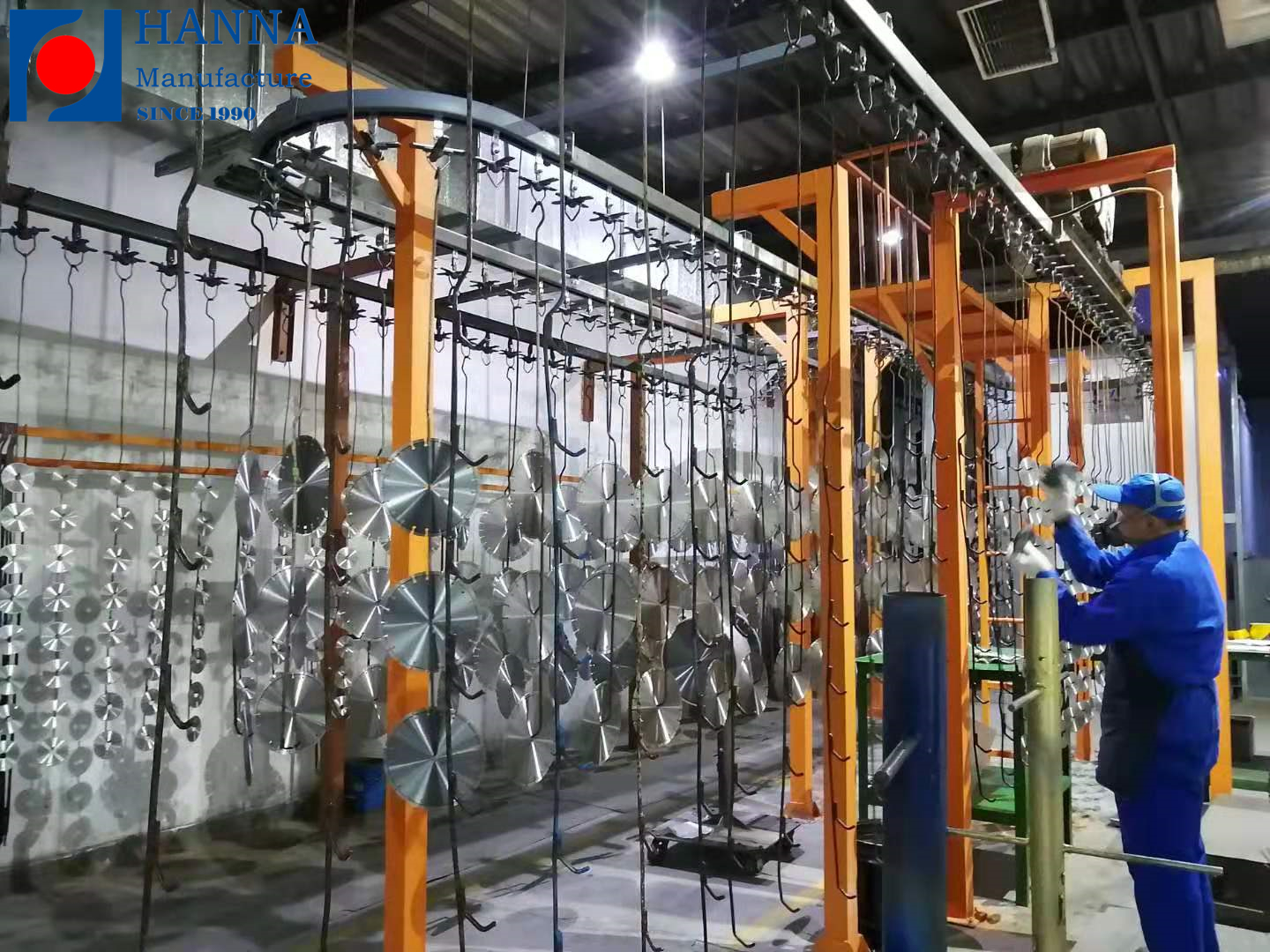

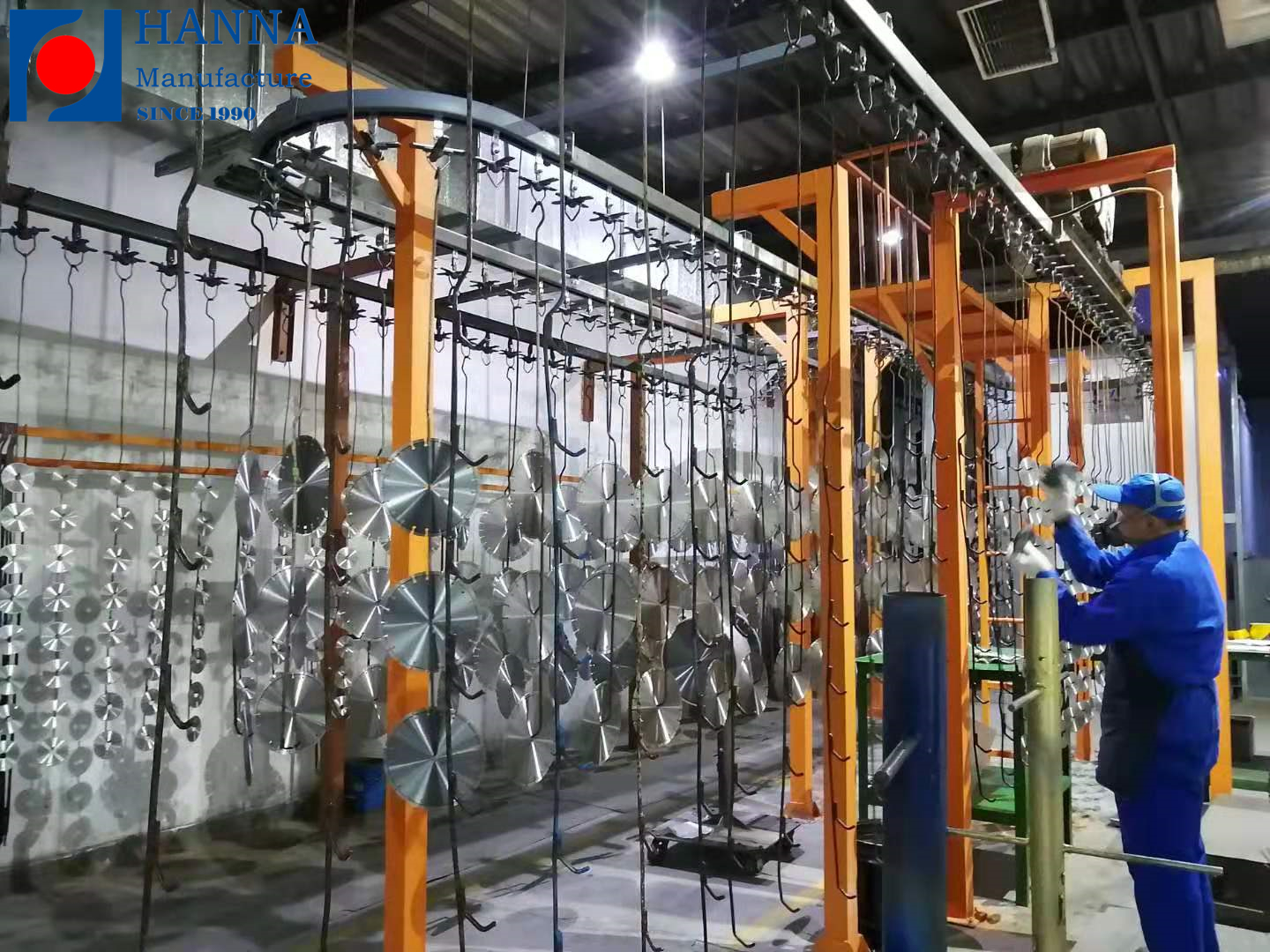

Conveyance: Automated powder coating conveyor systems for material handling through all stages.

Automation: Increasingly incorporates painting robots for precise, consistent application, maximizing efficiency and minimizing waste.

Liquid paint lines require:

Spray booths with powerful exhaust/scrubbing.

Mixing rooms.

Potentially longer drying tunnels or multiple staging areas.

Significant solvent storage and handling infrastructure.

Choose Hinah for Advanced Coating Solutions

The choice between powder and paint hinges on your specific needs: durability, aesthetics, volume, environmental goals, and budget. Powder coating consistently wins on durability, environmental compliance, operational efficiency for medium-high volume, and long-term cost savings. Liquid paint retains niches where specific, complex visual effects or very thin films are paramount.

As a premier powder coating system supplier, Hebei Hanna Technology Co., Ltd. (Hinah) designs and manufactures complete, high-performance powder coating equipment. From efficient powder coating booths and ovens to fully automated lines with painting robots, we provide tailored solutions that enhance quality, productivity, and sustainability. Explore our range of powder coating equipment for sale and discover how Hinah can transform your finishing process. Contact us today for expert consultation.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)