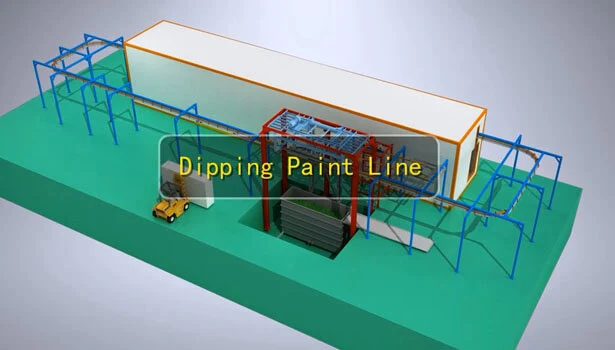

Increased Efficiency: Conveyor Paint Lines automate the movement of products, ensuring a continuous flow and reducing manual handling, which boosts overall productivity.

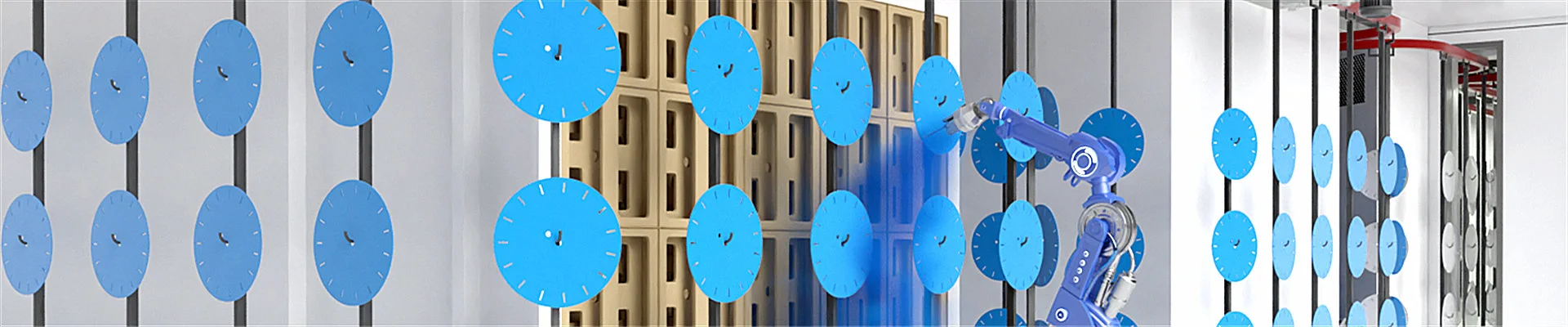

Consistent Coating: Automated systems provide uniform and consistent paint application, improving the quality of the finish and reducing defects.

Space Optimization: Conveyor systems save floor space by utilizing vertical and horizontal movement, allowing for more compact manufacturing layouts.

Reduced Labor Costs: With automation, the need for manual labor decreases, leading to lower operational costs and fewer chances for human error.

Versatility: Conveyor Paint Lines are adaptable, capable of handling a wide range of product sizes and types, making them suitable for various industries.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

_20250225.webp)

.webp)

.webp)