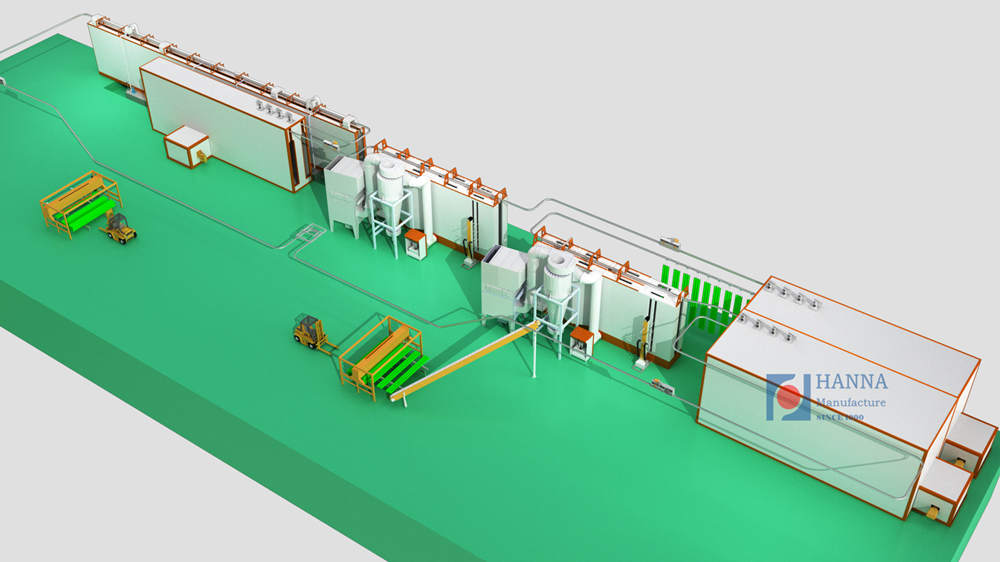

powder coating line for aluminum profiles offers significant advantages, including excellent corrosion resistance and durability, ideal for outdoor and high-performance applications. The process ensures a smooth, uniform finish that enhances the aesthetic appeal of aluminum products. Powder coating is also environmentally friendly, with no harmful solvents or emissions, making it a sustainable choice. The line is highly customizable, offering a range of colors, textures, and finishes to meet specific design needs. Additionally, the efficient coating process minimizes material waste and reduces energy consumption, resulting in a cost-effective solution for large-scale aluminum profile production.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)

.webp)