Features of E-Coating Line

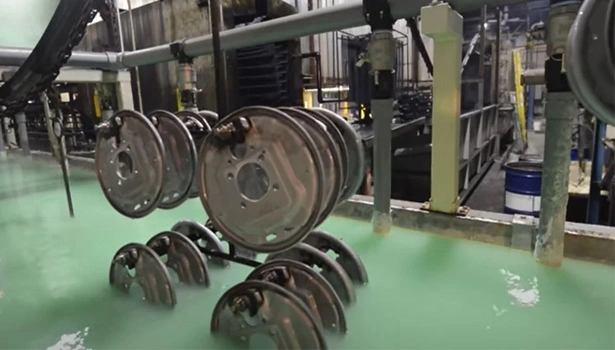

As a widely used coating technology in modern industry, electrophoresis line has many significant advantages, which are detailed below from the dimensions of process characteristics, production efficiency, environmental protection and economy:

I. Process quality advantages (presented in parallel form)

1. **Uniform and dense coating film**: The electrophoresis process utilizes the electric field to make the coating particles deposited directionally, which can cover the inner cavities of complex workpieces, weld seams and other dead corners, forming a coating film with uniform thickness and strong adhesion. For example, Zero Run C11 realizes 100% electrophoretic coverage of the cavity by 360° flipping the wire body, which significantly improves the anti-corrosion performance.

2. **High corrosion resistance**: Using materials such as epoxy resin or acrylic resin, combined with amino curing technology, the coating's salt spray resistance time generally exceeds 1,000 hours, which effectively prevents the metal substrate from rusting. The electrophoresis process of the whole vehicle of Yutong Technology even reaches the standard of 10 years without structural corrosion.

3. **Diversified Decorative Effect**: By adjusting the coating formula and process parameters, special textures such as matte and pearlescent can be presented, while maintaining the natural luster of the metal substrate.

II. Production efficiency and automation advantages

The electrophoresis line is highly adapted to automated flow operation, and through the intelligent control system (such as Germany Durr, Japan Paca design line body), continuous production can be realized, and the beat can be shortened to less than 3 minutes. The fully automated line reduces manual intervention and labor intensity, while guaranteeing the consistency of product quality. For example, Chery Wanda electrophoresis line covers all-material electrophoresis for 12-meter vehicles, with both capacity and precision.

III. Advantages of Environmental Protection and Economy

1. **Excellent environmental protection**: Using water as solvent, the emission of volatile organic compounds (VOC) is extremely low, and the new non-phosphorus vitrification pretreatment technology avoids heavy metal pollution. The utilization rate of paint is as high as 90%-95%, far exceeding the spraying process.

2. **Energy saving and consumption reduction**: Intelligent design reduces baking energy consumption, and natural gas heat source and waste heat recovery system further reduce carbon emission. For example, the electrophoresis line of Guangxi Hengda Elevator meets the national energy-saving and emission reduction requirements through high utilization rate coating and energy-saving equipment.

IV. Adaptability and application range

Electrophoresis technology is applicable to a wide range of metal materials such as steel, aluminum, galvanized sheet, etc., and can handle irregularly shaped workpieces. By adjusting the tank parameters (e.g. pH value, electrolyte concentration), it can flexibly meet the needs of different industries, covering automotive, hardware, furniture and other fields.

Summary

With its core advantages of **high-quality coating, high-efficiency production, environmental protection and energy saving, and wide applicability**, electrophoresis line has become a key technology for upgrading modern manufacturing industry. With the progress of automation and material science, it will continue to play an important role in enhancing the added value of products (e.g. automobile appearance and anti-corrosion performance) and promoting green manufacturing.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)