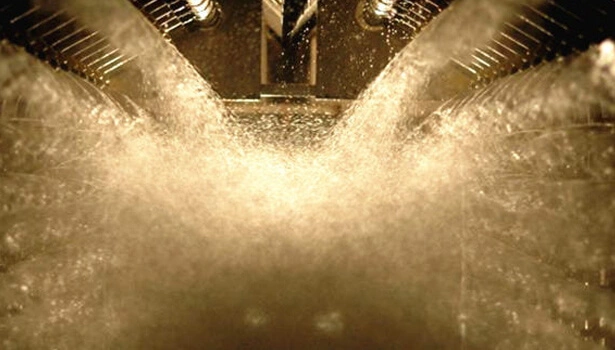

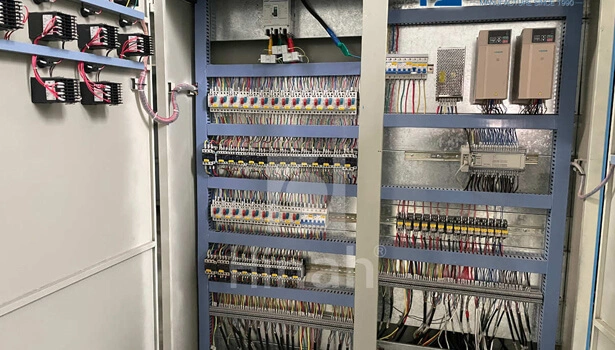

Key accessories include the E-Coat Tank, Thermostatic Equipment, Dosing System, Ultrafiltration Equipment, Power Supply System, Washing Equipment, and Electronic Control System. Each component is designed to optimize the electrocoating process for better performance and consistent results.

-

Powder Coating Line

- Automatic Powder Coating Line

- Manual Powder Coating Line

- Powder Dip Coating Line

- Vertical Powder Coating Line

- Horizontal Powder Coating Line

- Small Powder Coating Line

- Aluminium Powder Coating Plant

- Almirah Powder Coating Plant

- Conveyorised Powder Coating Plant

- Industrial Powder Coating Systems

- Powder Coating Equipment

- Painting Line System

-

E-Coating Line

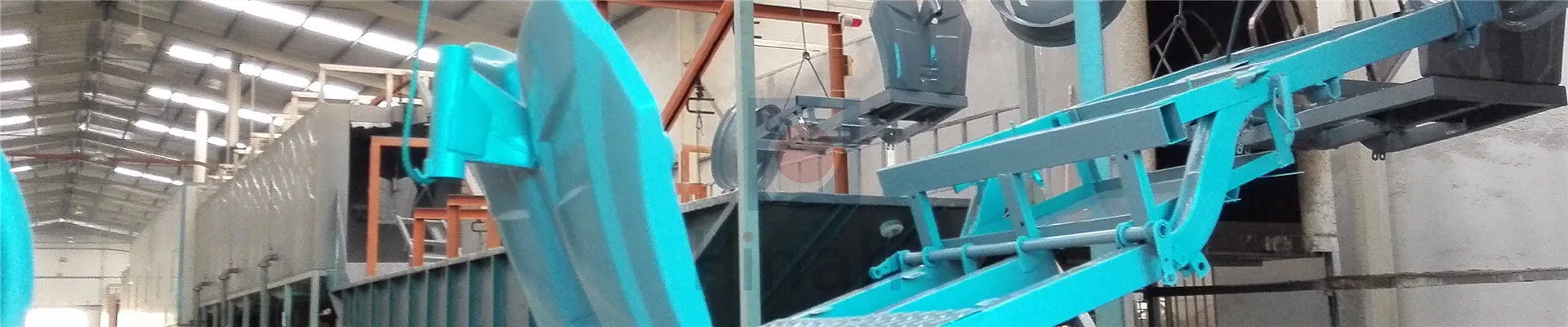

- Monorail E-Coating Line

- Gantry Stepping E-Coating Line

- Accumulation Conveyor E-Coating Line

- Trolley Hoists E-Coating Line

- E-coating System Accessories

- Aluminum Products E-Coating Line

- Automotive Body E-Coating Line

- Automotive Parts E-Coating Line

- Small Electric Cars E-Coating Line

- Power Moto Tricycle E-Coating Line

- Electric Appliances E-Coating Line

- Castings E-Coating Line

- Stainless Steel Products E-Coating Line

- Support

- About Us

-

Get a Quote

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)