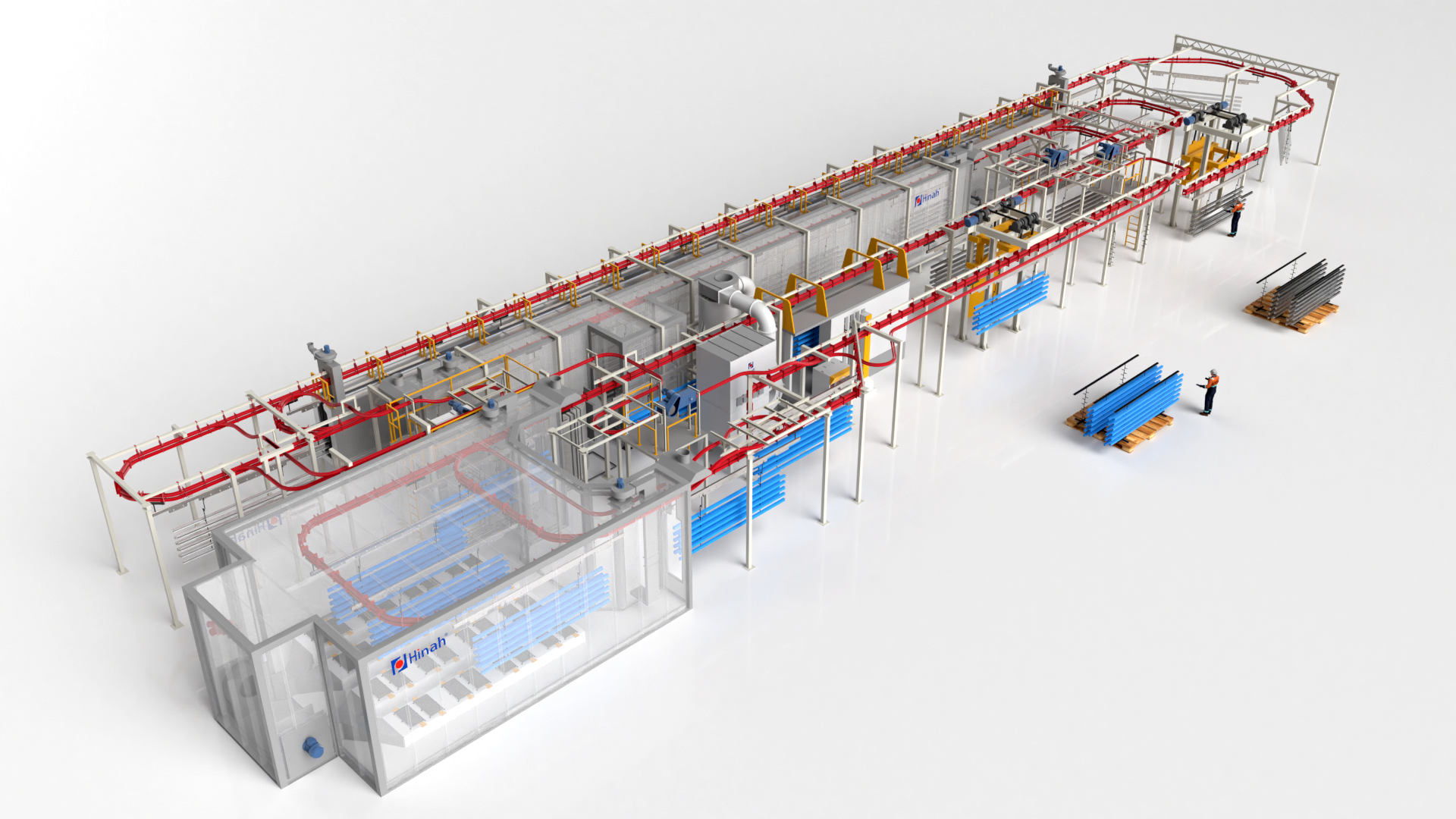

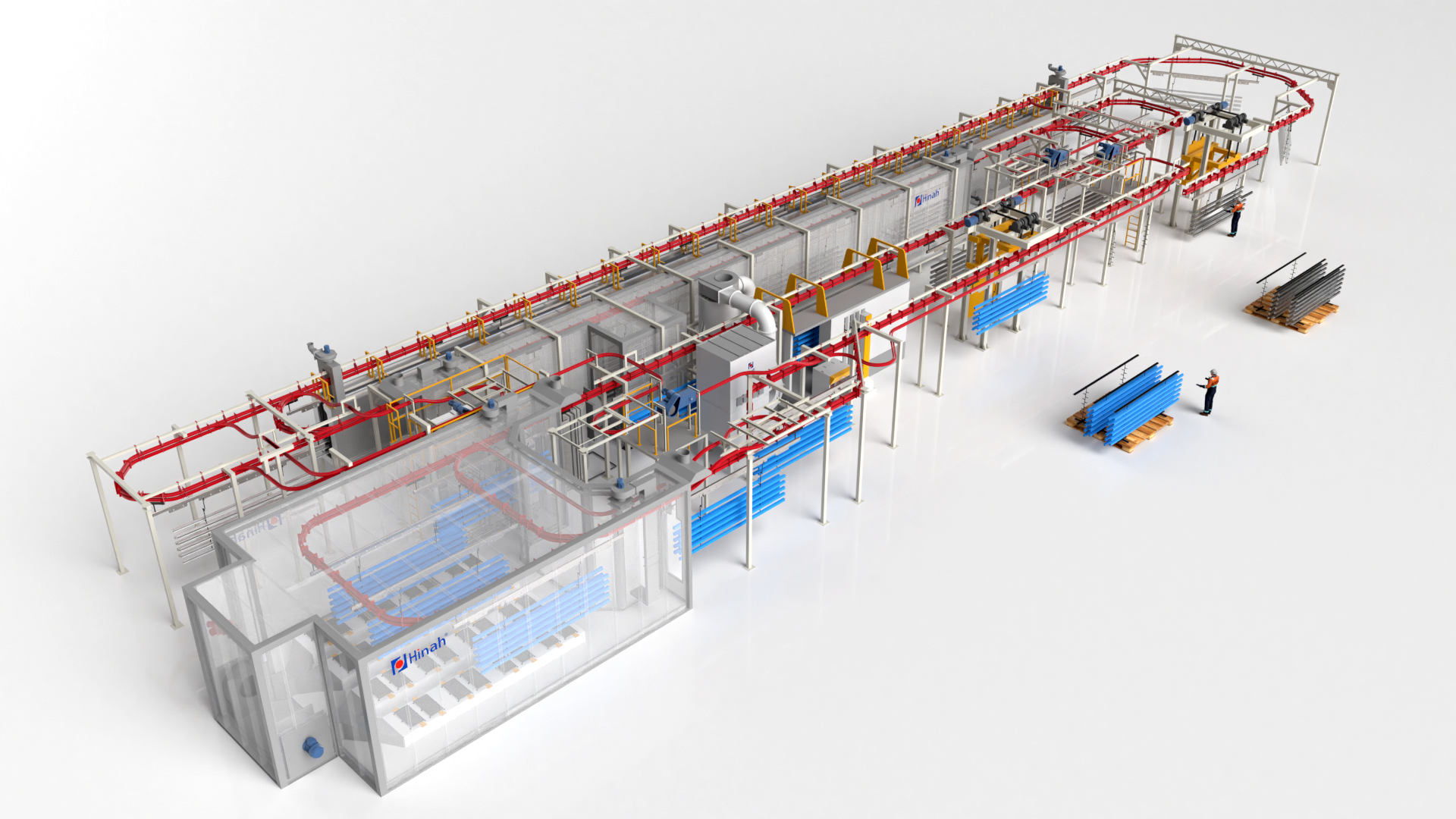

Efficient Automated Powder Coating Line Solutions

The core of an automated powder coating line lies in the selection and configuration of equipment. A highly efficient automated powder coating line typically includes various stages such as pre-treatment equipment, coating equipment, curing ovens, recirculation systems, and control systems. Pre-treatment equipment is primarily responsible for cleaning and surface preparation of the workpieces to ensure optimal coating adhesion and quality. The coating equipment is the critical component of the entire production line, as its performance directly impacts the uniformity and adhesion strength of the coating. The curing oven is used to heat the coated workpieces, allowing the powder to melt and form a solidified film.

Introduction of Automation Control System Significantly Enhances Overall Efficiency

The automated powder coating line is equipped with a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) system, allowing operators to easily monitor and adjust the production line in real-time. The system automatically identifies the type and quantity of workpieces, optimizes the spraying and drying times, thus reducing human error and improving production efficiency. The data collection system continuously records various data throughout the production process, providing valuable insights for future production analysis and improvements.

Rational Layout for Improved Efficiency

The design of an automated powder coating line also plays a crucial role in boosting efficiency. The different stages of the production line should be closely integrated to avoid time losses caused by workpiece transfer. Typically, chain conveyors or roller conveyors are employed to improve workpiece flow efficiency. Movement between stages should be optimized to reduce unnecessary pauses, ensuring a smooth production process.

Another critical technology is the implementation of a powder recovery system. In traditional coating processes, the waste of powder coating materials is a significant concern. By implementing an efficient powder recovery system, the unused powder that doesn't adhere to the workpieces can be collected and processed for reuse, reducing production costs and improving resource utilization. This not only aligns with environmental protection standards but also helps businesses save on material costs.

Equipment Maintenance and Care

In practical operations, equipment maintenance and care cannot be overlooked. Regular cleaning and maintenance of coating equipment can significantly extend the lifespan of the machinery and ensure the efficient operation of the production line. Companies should also provide ongoing training for operators, enhancing their professional skills and safety awareness to ensure smooth and safe production processes.

Intelligentization of Automated Powder Coating Line

By incorporating IoT (Internet of Things) technology, the production line can achieve higher levels of intelligent management. Equipment can communicate with each other in real-time, sharing production data and optimizing scheduling. This intelligent production model not only improves production efficiency but also allows for better adaptability to changes in market demand, providing businesses with a competitive edge.

Building an efficient automated powder coating line requires comprehensive consideration of factors such as equipment selection, system integration, production layout, powder recovery, and staff training. By continuously optimizing these elements, businesses can enhance production efficiency, reduce costs, and ensure product quality. In the future of industrial development, powder coating technology is expected to play a greater role, contributing significantly to the growth of various industries.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)